3 Ways To Create Curved Structures Using Bamboo

By Sai Goutham | March 26, 2021 | Resources - Processing -

Bamboo has endless possibilities and when combined with creativity, it can lead to a wide range of interesting shapes. In its natural form, it is a straight, slightly tapering pole. But how do we bend it to create fluid, dynamic spaces?

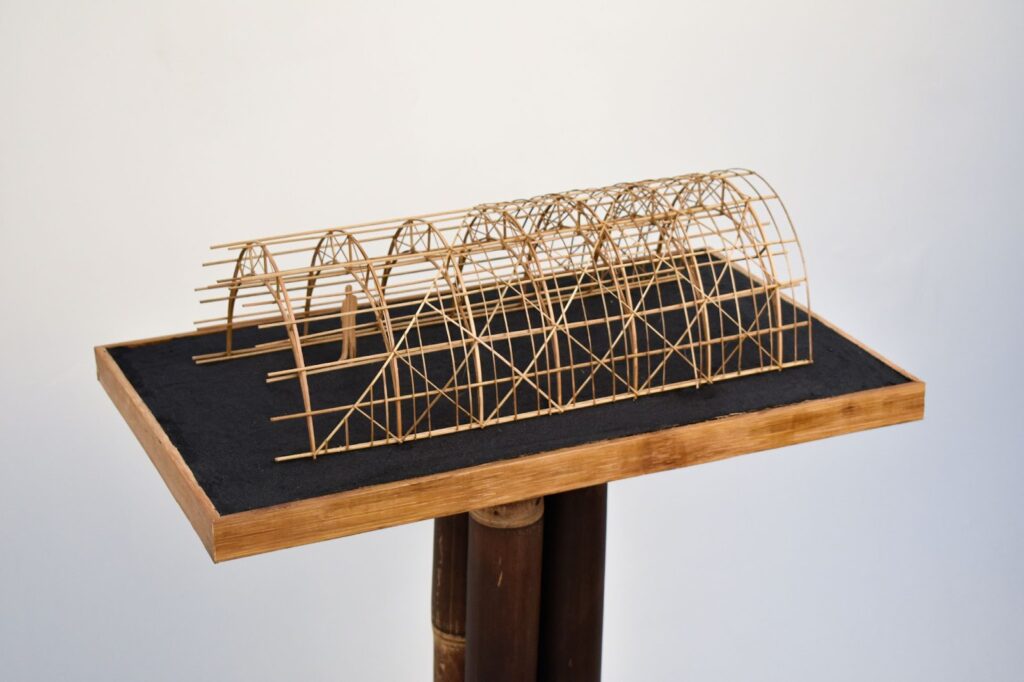

At Bamboo U, we seek to share various bamboo design, carpentry, and building skills. The rising enthusiasm for this material has allowed us to support people to push the limits of this material. To begin to understand the potential of this material we encourage students to begin by experimenting with the material using handmade scaled bamboo models.

During the 11 Day Immersion guest facilitator, Scott Vandervoort, guides participants to create animal abstracts, which helps them to understand the flexibility of bamboo and creatively explore different forms. They move from literal representations of animals to abstract ones.

How Bamboo Bends

Bamboo is naturally flexible and can be flexed into a slight bend and simple framed structures can be built using bamboo's natural straight form. However, it requires specific techniques to achieve extensive curvilinear forms. In the structures we build here in Bali, there are 3 techniques we to create curved structures using bamboo. These are:

- Rup Rup

- Split Members

- Lidi Bundles

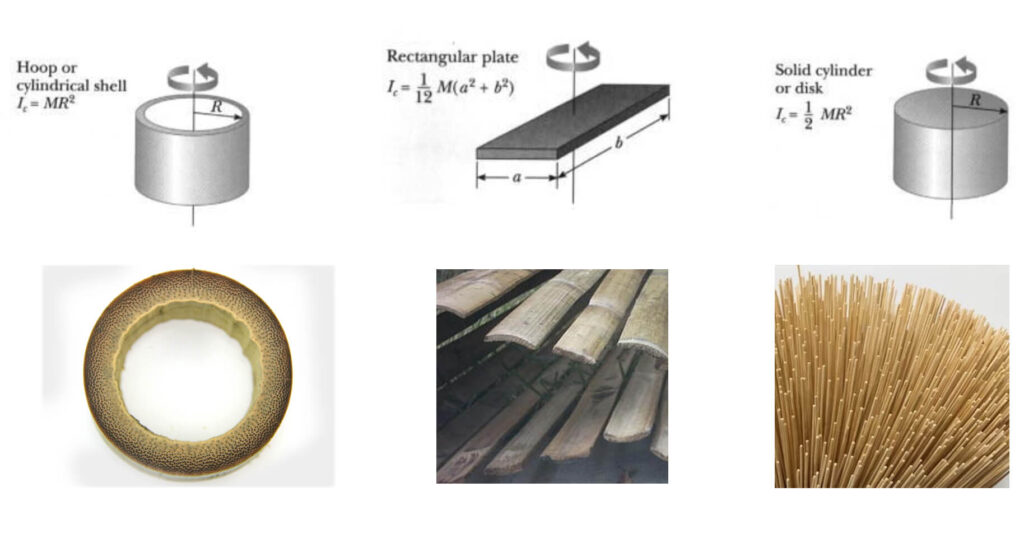

Before learning to bend bamboo we need to understand the moment of inertia of different cross-sections of the type of material we use for these techniques.

In a simpler way, a smaller surface area and solid form will have more flexibility compared to a hollow cylindrical form. Full poles have less flexibility than splits and splits have less flexibility than lidi bundles (full poles < splits < lidi).

For the rup-rup technique, we use full-round pole bamboo in its natural form. For the split members technique we use bamboo splits which are wide and flat rectangular shaped slats and for lidi bundles, we also use bamboo splits which are thinner and in a solid cylindrical form.

1. Rup-Rup

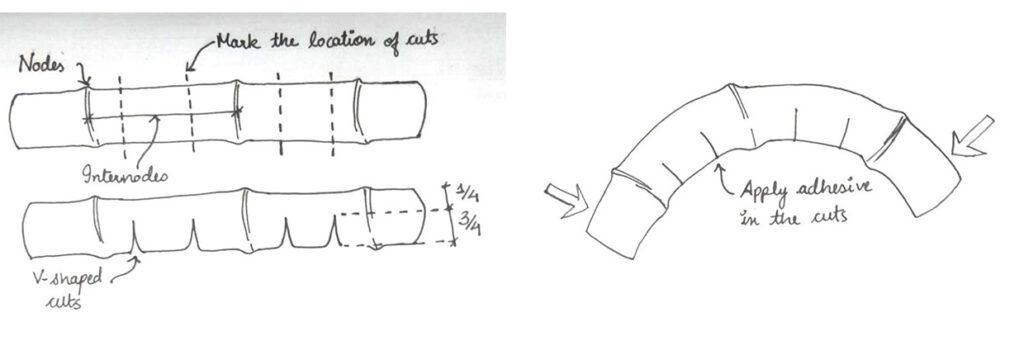

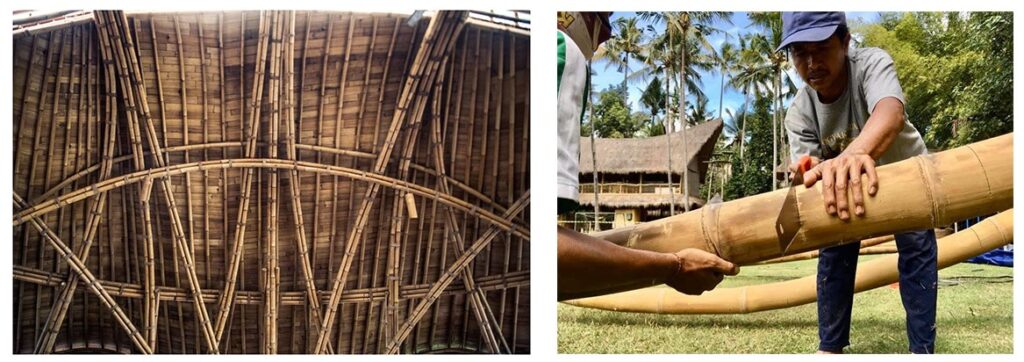

Shaping and curving whole, hollow bamboo poles in their natural form is challenging because of their cylindrical profile but it can be done using the rup-rup technique. This is a process where v-shaped cuts are made along the axis of the bamboo pole wherever it is necessary to achieve the shape we require.

It is important to note that this cutting of the wall culm reduces the structural integrity of the full poles to only the part that has not been cut, which is just a split. For structural members to maintain structural integrity, we bundle two or more full-bamboo poles together as per our requirement. We bolt them together with threaded rods and bamboo pins to ensure there is no moment in the bundle.

This technique is used to make elements like structural arches, ridge members for roofs, furniture, and decorative elements like railings. Dendrocalamus asper locally known as Bambu petung and Gigantochloa apus locally known as Bambu tali are commonly used for the structural elements and Bambusa Blumeana locally known as Bambu duri for furniture and decorative elements.

The new Green School Bali gym designed by IBUKU is the largest arched structure in bamboo of its kind in the world and is composed of 18 arches, which are built on the ground using the rup-rup technique. They have bundled 6 Dendrocalamus asper poles to achieve structural integrity according to the design.

Mepantigan auditorium and Turtle classroom, also at the Green School, designed by IBUKU are some other examples of structures built using the rup-rup technique. Have a look at more details on the Mepantigan auditorium and the Turtle classroom.

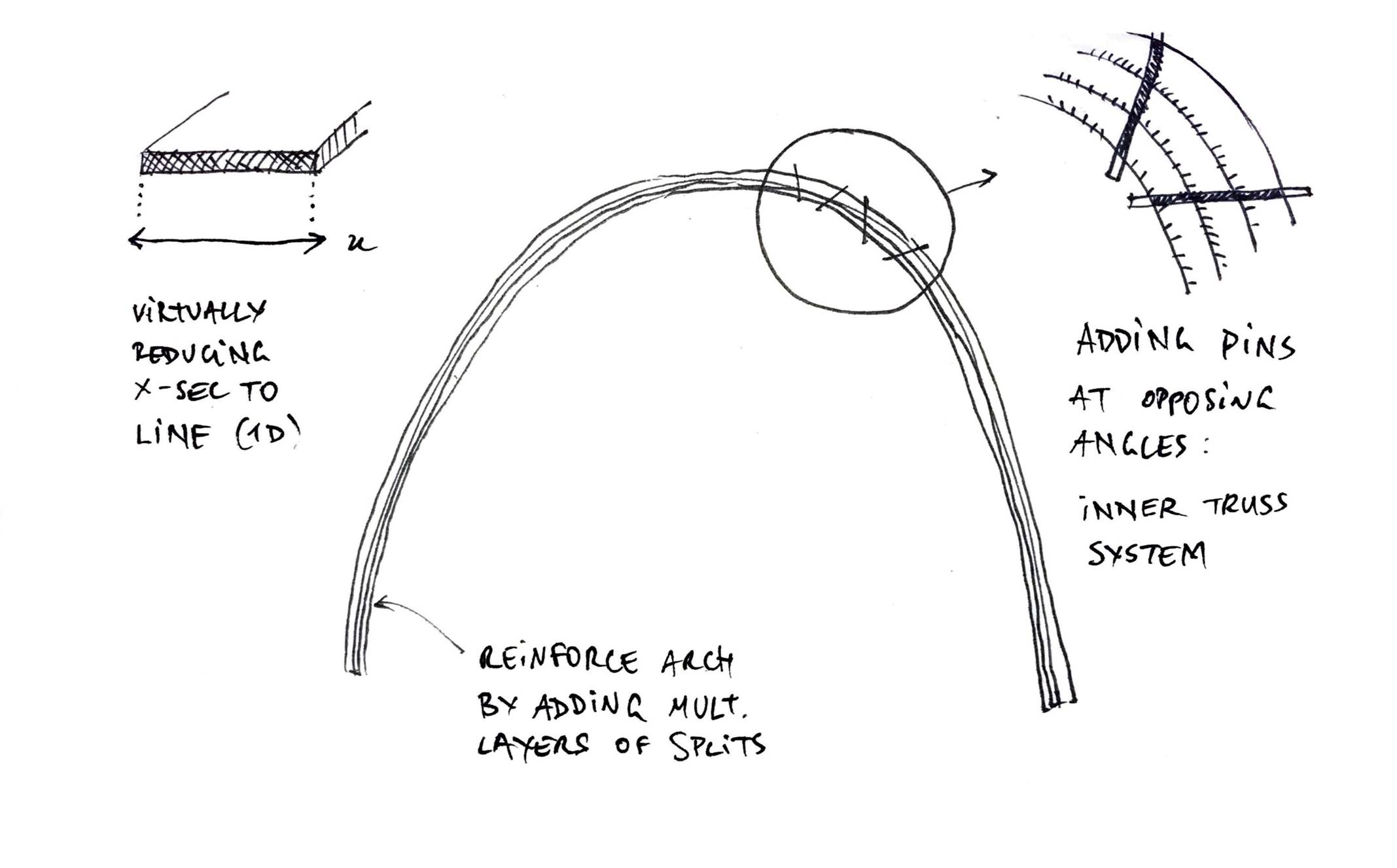

2. Splits

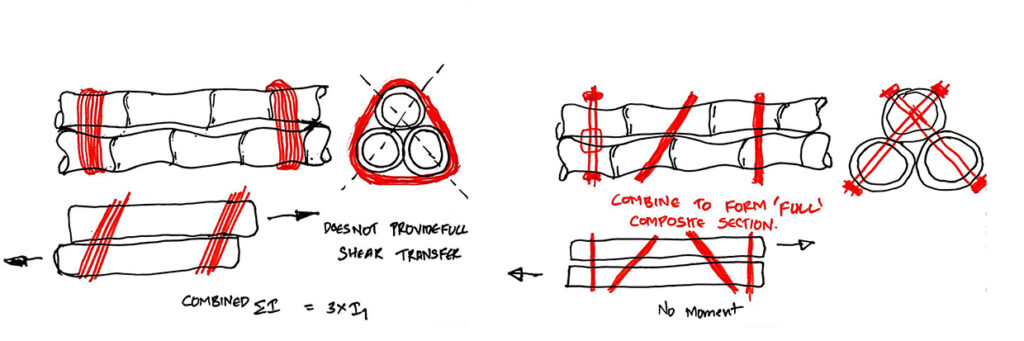

Bamboo laths or splits are made by splitting full bamboo into strips. Splits have been used traditionally in a wide range of products. We have been experimenting with building using splits in various applications. Very strong and lightweight structures can be built using bamboo’s best property “tensile strength” with splits. Splits have freedom in bending and the arching systems can be shaped easily.

For some structural members to have structural integrity, we use a clump of bamboo splits tied together called a split bundle. The elements are assembled on the ground using templates and installed into place easily. Dendrocalamus Asper splits are used for structural elements and Gigantochloa Apus for non-structural elements. The splits are glues together, the split bundles are pinned together with bamboo pins in opposing angles to ensure there is no moment in the bundle.

Splits are commonly used to make arches, ridge members, walls, flooring, ceilings, doors, windows, and furniture.

The pool hang-out pods at the Bamboo U campus is one of the best examples of how to build beautiful woven bamboo structures using splits.

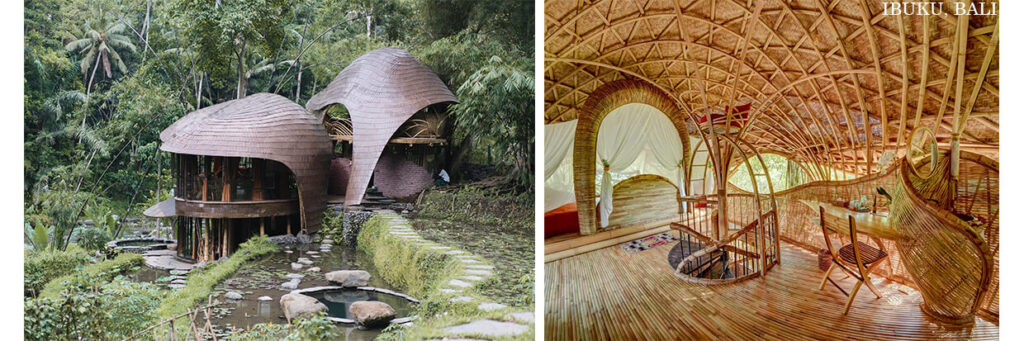

River Bend house at Bambu Indah designed by IBUKU is one of the best examples of a grid-shell structural system built using splits.

To know more about a typology of how to build with bamboo splits check out our Pool hang-out pods article, and River bend house at Bambu Indah article.

3. Lidi Bundles

Lidi bundles are hand whittled thin, long, and solid circular bamboo sticks bundled together. The result is a curved and flexible element that is adjustable in shape, dimension, and length.

The flexibility of lidi bundles complements the organic and curvilinear roofing structures more beautifully and artistically. Sharma springs, a six-level bamboo residence designed by IBUKU, is one of the best buildings that exhibits the use of the lidi bundle.

To know more about the Sharma springs residence have a read through this article.

Lidi bundles are tied together on the ground by hand and tightened by metal clamps to ensure they are tightly held together. The bundle is carried to site and installed in place using vertical supports. Lidi bundles need to be bound together carefully, paying special attention to each strip’s individual placement. Lidi bundles are used to make both structural and decorative elements.

On the Bamboo U campus, we used a giant lidi bundle to shape the roof of the Dapur Naga project, during the 11 Day Immersion in May 2019. All the participants allied together to hold up the bundle before we added the Dendrocalamus asper niger supports.

The properties of lidi bundles allow us to bend in 3 dimensions - double curvature. This allows for the creation of anticlastic surfaced bamboo structures (“Anticlastic surfaces are a double-curved surfaces which have principal curvatures on the opposite sides of the surface.”).

The Meditation space at Green Camp and Dapur Naga on the Bamboo U campus are some of the best examples of anticlastic surface bamboo structures at different scales built using lidi bundles.

Want to know more about how to bend bamboo to create beautiful curving structures? All of the building techniques mentioned in this article are a feature of the upcoming Bamboo U Online Immersion. For more info on the online course, please click the link below:

Sai joined the Bamboo U team in March 2020 as Research & Development Manager. He is also a natural builder and an architect from India. He has managed many mud and bamboo projects over the years.

June 7-18, 2024

The 11 Day Bamboo Build & Design Course in Bali

In 11 days, we'll show you how to build bamboo structures we’ll share all that it takes to build with nature.

April 26, 2024

The Fundamentals of Building with Bamboo Online Course

All the fundamentals you need to get you started working with bamboo. Deep dive into cinematic videos and step-by-step guides that will provide you with a strong understanding of bamboo as a design and building material.