Designing a Multipurpose Bamboo Shed in Australia

By | May 19, 2025 | Student Work -

For her Bamboo U Online course project, Shelley designed this multipurpose shed structure. She intends to build this project in the coming months, using locally-sourced bamboo.

Hi! I’m Shelley Shaw. I studied Bachelor of Architecture 20 years ago. Now my husband, 3 kids and I have live in Far North Australia, where there is plentiful supply of Bamboo.

Curious about bamboo construction techniques and keen to connect with bamboo designers, I enrolled in the online course at Bamboo U. I was a bit apprehensive at first, what could they possibly teach me online? Well, I was suitably impressed with the course structure, content and best of all the networking opportunities.

The course has a fantastic group of tutors and students sharing their experience and ideas for future projects. The interactive lessons provided useful information on design strategies, current projects from architects working in the field and very useful engineering tables for structural members. Each lesson, the experts welcomed questions and discussions, sharing their experiences with different designs and techniques, which was really useful when trying to design a utility shed that I actually want to build.

Related: Designing a Vegan Art Studio with Hyperbolic Paraboloids

On our hobby farm, we needed an open shed as weather protection for projects, recreation, and storage. This was the perfect opportunity to design with, build with, and learn about bamboo.

The shed must be open and breezy. The floor space must be clear, with large spans to allow for parking vehicles, kids gymnastics or building projects.

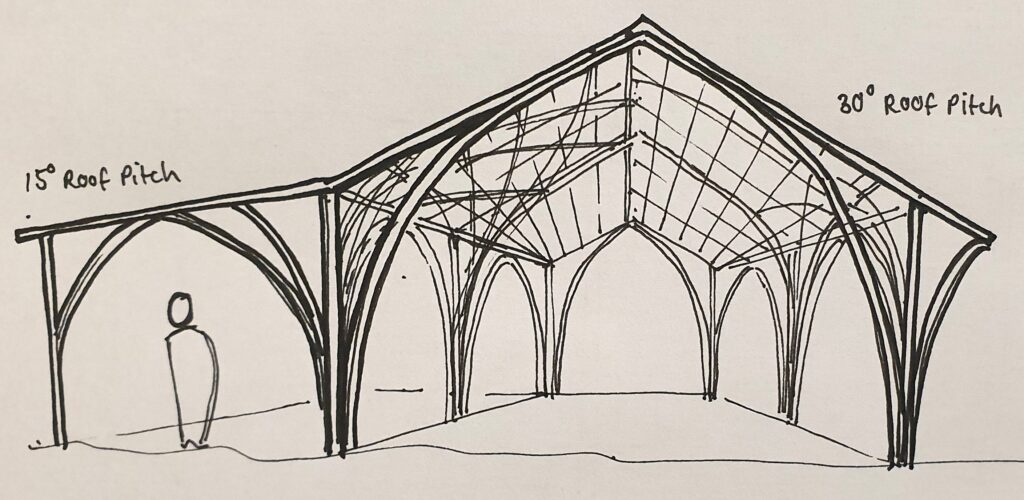

As for the site, the climate is subtropical with heavy rains in the wet season. It’s on private land in the bush. Because of this, I wanted to evoke elements of the natural environment. In particular, I love the aesthetic of arches, which are similar to the forest’s tree canopy.

The parameters I had to work with were:

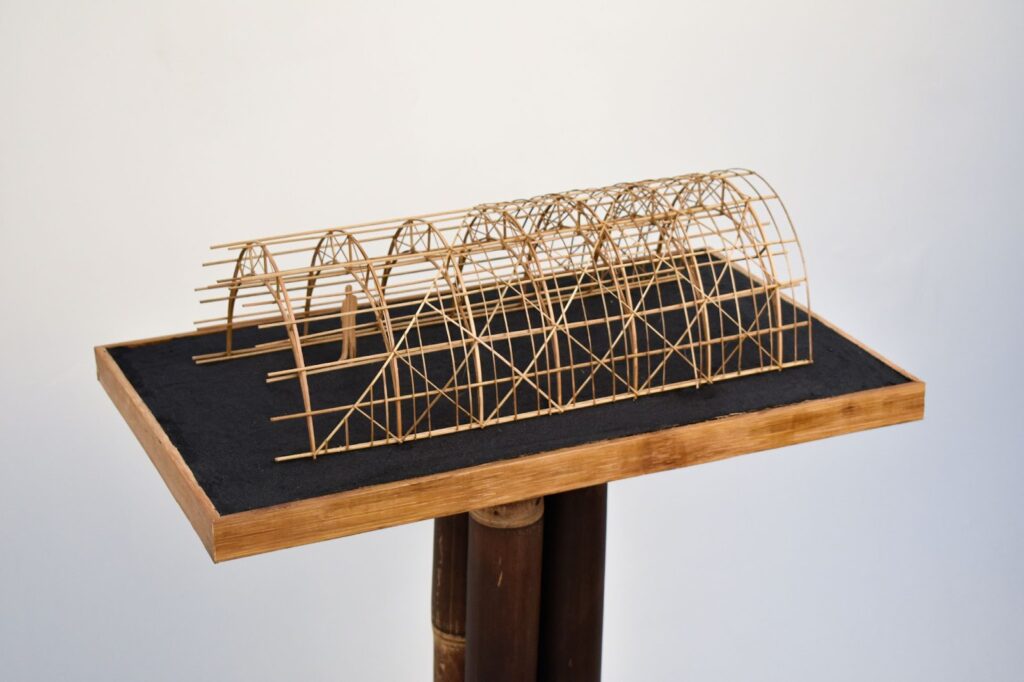

The process of building the scale model was invaluable, it allowed me to explore and think about the construction process required to build the shed. I began with the idea of building 3 A-frame portals on the ground then raising them into place. I would use fish-mouth joints to attach the primary columns to the roof. Additionally, I wanted to employ steam bending or use the rup-rup technique (if need be) to curve the bracing members.

As the course progressed, we learned more about different techniques, it was also very useful to hear new developments in bamboo design. As such, I adapted my design. Firstly, to make the build easier. And secondly, with the intention of reproducing and testing members for the bamboo industry’s evolution in Australia.

Related: How to Get Started with Bamboo Model-Making

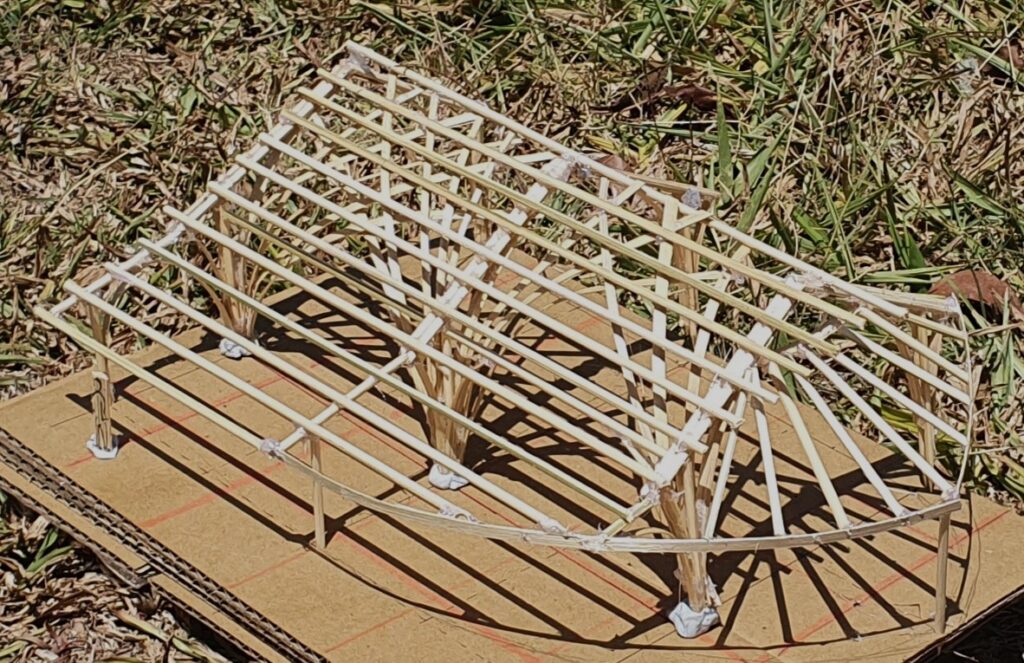

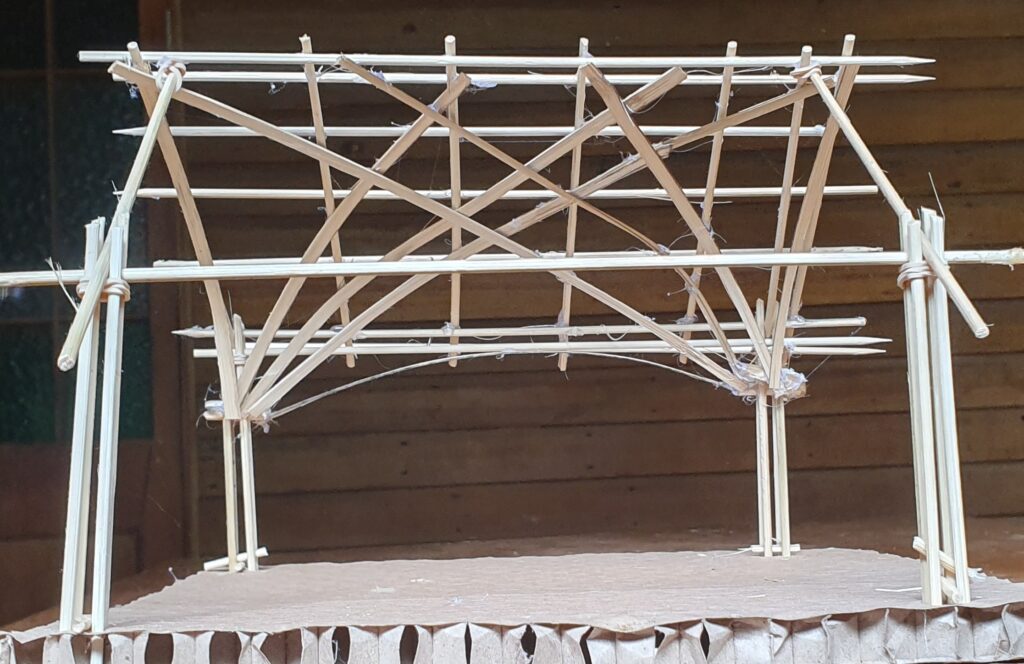

This development incorporates in situ construction, using smaller diameter bamboo as columns which are easier to bend. Here, the bamboo is lashed together, requiring less carpentry skill than fish-mouth joints. Meanwhile for the roof, bamboo strips, tied and glued together create long, curved, and very strong cross bracing, which doubles as a decorative ceiling.

Most of the shed is very open plan and utilitarian. However, at the North-Eastern end, there is a cozy nook, made from splits. This creates a different space for resting, morning tea, reading etc.

The task of building this model is still a little daunting for a first-time builder – there are many elements and perhaps it’s too busy and complicated for a simple shed. Luckily, I keep up-to-date with the projects at BambooU and the post and beam design for the Dec 2024-build helped give me an idea on how to simplify the design.

I will incorporate interlocking columns, as also used in some projects by Jorg Stamm. This will create a strong, clean and simple design. From the interlocking connections near the top of the columns I can fasten a circle made of splits as the base for the curved roof bracing. Using the engineering tables introduced to us by guest speaker David Trujillo, I know that I need to use two of my 150mm diameter bamboo poles and bracing support to span the 6m.

The best part of being a student at BambooU, is it doesn’t just finish with the course. I am so inspired to try out my own project, with confidence of knowledge from the course plus retaining the connections to bounce ideas off in future. Through the course, I have learned from other students, am updated with projects from around the world, and I know that if I need help with my project, I can always reach out to the team from Bamboo U.

I look forward to updating my project with photos of the actual build! The estimated completion date is December 2025.

Want to design your own bamboo project but not sure where to start? Join us for one of our in-person or online workshops HERE.