How Do You Protect Your Bamboo Structure From Fire?

By Layane Al Madani | September 20, 2022 | Construction - Processing -

While bamboo, as an organic material, is naturally flammable, the extent of bamboo’s fire resistance depends on the material’s treatment, processing, and use in design. From mixed-material use to engineered products, bamboo’s safety in fires has been optimized in various ways.

Bamboo is a flammable but potentially fire-resistant material. The extent of bamboo’s fire resistance depends on the material’s treatment and processing, and on its use in design. Through optimal preparation and design, bamboo buildings, both in round-pole and in engineered form, can be fire-safe. It is important to note that fire-safe buildings don’t always mean fire-proof - fire-safe buildings are designed to decrease the chances of fire spreading and causing damage to human life. There is great potential in creating safe bamboo buildings appropriate for various contexts.

In this article, we will look into:

- Is bamboo flammable?

- Design for fire resistance

- Advances in technology and engineered bamboo

Is Bamboo Flammable?

Bamboo is a flammable but potentially flame-resistant material. The extent of the material’s fire resistance depends on its treatment and processing. Like many of the flammable materials and products that surround us on a day-to-day basis, bamboo doesn’t have to be fire-proof to justify building with it, rather, it requires learning how to best use it safely. If we build with bamboo according to its properties and are aware of its limitations, we can limit fire risks.

One of the properties that make bamboo so desirable as a low-carbon material is also one that makes it flammable - bamboo’s high sugar content. Using bamboo of an appropriate age for construction is vital, and the next important step to take is treating the bamboo before building with it. At Bamboo U, we teach about the importance of treating bamboo, which can extend the lifespan of bamboo buildings from only four years to an entire lifetime. We promote a range of treatment methods, many of which are borate-based. Boron is the most widely used chemical compound to treat bamboo for both construction and products. Borates can be effective for fire retardancy in higher concentrations, making the bamboo burn slower. The use of additional flame coatings or treatments should be carefully considered because they can prevent end-of-life applications in the bamboo’s circular life cycle, while borate-treated bamboo can be used in a circular manner.

Design for Fire Resistance

Building codes can be useful guidelines in many contexts, but for a material that is considered new to the field, such as bamboo, codes may not be up to speed with the research. This is similar to how fire safety building codes in many countries are not in favor of wood, yet many studies show that wood buildings burn slower than steel buildings. Therefore, understanding bamboo in its different forms and designing it according to these properties is particularly relevant to building a fire-safe bamboo structure.

To do so, we need to consider firstly, the type of bamboo product and secondly, the part of the structure in question. Designing with bamboo can include round poles, processed products, and engineered products. For example, processed bamboo products such as splits and bamboo mats burn a lot faster than round poles, because the outer skin of bamboo is the most fire resistant. Therefore structural members should not be made from these products without extra fire coating. It is also worth evaluating whether a structure should be made entirely of bamboo - the benefits of bamboo can still be taken advantage of in mixed-material buildings. For example, some argue that bamboo roofing should be avoided, due to the flammability of the bamboo products generally used for roofing. It is valuable to consider each structural element separately when designing - the flooring, walls, ceiling, and roofing will each require different specifications.

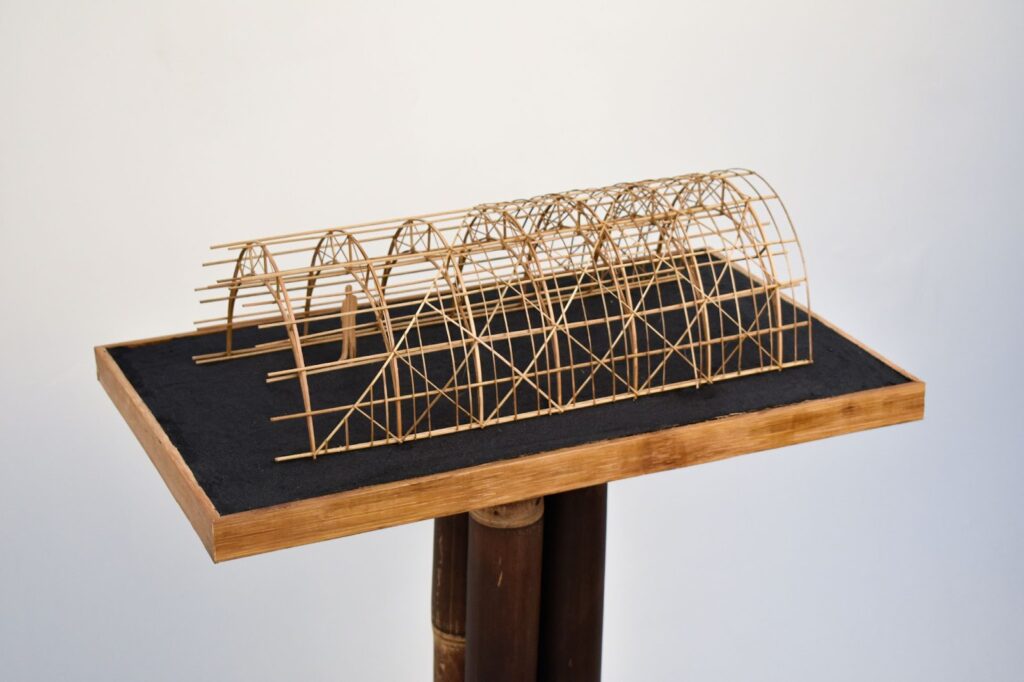

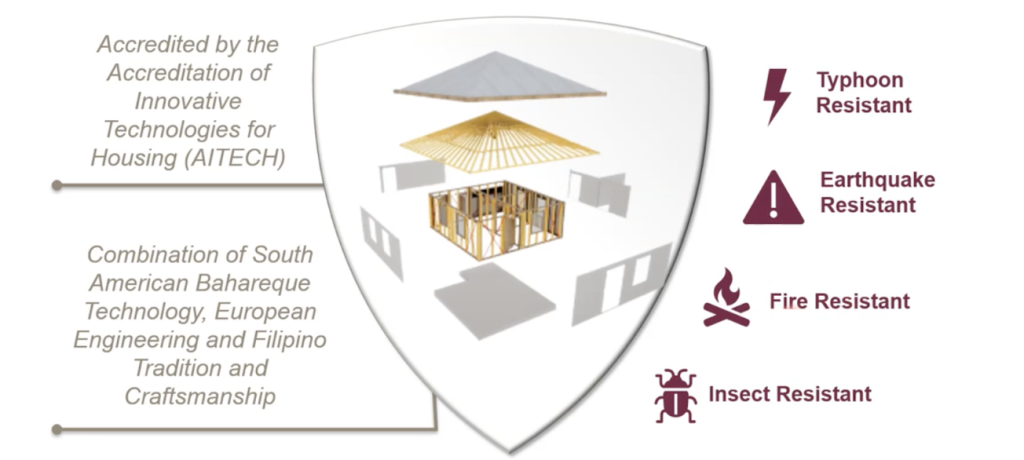

An example of a fire-safe bamboo design using mixed materials is the engineered bahareque shear wall. Encompassing bamboo with a fire-resistant material has proved a convenient way to protect the bamboo from fire, while still using it as a structural member. While this structural system uses cement, it still has a 60-70% lower carbon footprint, and research is going into how the earth can be used instead. An example of this system in use is in Base Bahay’s work in the Philippines, where Luis Felipe Lopez, an expert speaker at Bamboo U, is head of technology.

Advances in Technology and Engineered Bamboo

Similarly to timber’s journey to being increasingly trusted as a fire-safe construction material, advancements are being made in research and technology dedicated to testing bamboo and developing engineered products. While timber and bamboo have some different properties, the acceptance of timber in the construction industry is helping to pave the way for bamboo, which has the potential to be used in similar applications.

While here in Bali we try to maximize the use of round pole bamboo, we understand that in some contexts the use of engineered bamboo is more appropriate. An expert speaker at Bamboo U, Pablo Van der Lugt, has spoken about the advancements made at MOSO Bamboo, producing high-quality and fire-safe bamboo products applicable to almost any context. For example, products such as thermally modified bamboo, treated for outdoor use, have proven to be very fire resistant, even without further fire retardancy. Additionally, studies have shown that laminated bamboo is more difficult to ignite than traditional timber species used in construction, showing a promising application for the material.

With correct treatment and processing, and carefully considered design, bamboo structures can be fire-safe. While more research is going into the use of bamboo in structures, we can learn from what is already known to safely build with this material. To hear more about bamboo treatment, processing, and engineering, and about testing bamboo’s properties, directly from our Bamboo U team and experts, such as Pablo Van der Lugt and Luis Felipe Lopez, check out our Bamboo U Online Course.

In more exciting news, our two July and August 11 Day Design and Build Courses featured experiments with heat-bending bamboo, exposing the material to a direct and concentrated heat source. Our first impressions were that the pole’s strength was minimally compromised, opening up an exciting avenue to explore the relationship between fire and bamboo!

Sources:

INBAR, Bamboo and Rattan Update, https://www.inbar.int/wp-content/uploads/2022/01/BRU_V2I4_INBAR_Building-Future-With-Bamboo.pdf

INBAR, Design Guide of Engineered Bahareque Housing, https://bambuecuador.files.wordpress.com/2018/01/2016-design-guide-for-engineered-bahareque-housing.pdf

Gernot Minke, Building with Bamboo (book)

University of Queensland, Fire-safe bamboo structures – a methodology to facilitate performance-based design, https://discovery.ucl.ac.uk/id/eprint/10094300/1/Fire-safe%20bamboo%20structures%20%E2%80%93%20A%20methodology%20to%20facilitate%20performance%20based%20design-accepted.pdf

Layane is an architect with a specialization in urban resilience. She is passionate about vernacular architecture, social equity, and decolonized practices.

June 7-18, 2024

The 11 Day Bamboo Build & Design Course in Bali

In 11 days, we'll show you how to build bamboo structures we’ll share all that it takes to build with nature.

April 26, 2024

The Fundamentals of Building with Bamboo Online Course

All the fundamentals you need to get you started working with bamboo. Deep dive into cinematic videos and step-by-step guides that will provide you with a strong understanding of bamboo as a design and building material.