Experimenting New Methods For Testing Bamboo Trusses

By Wyly Brown | December 29, 2023 | Bamboo U Built Projects -

Experimenting with bamboo to replace structural steel in conventional commercial architectural applications.

Standardized Bamboo Trusses

Bamboo design and architecture is a growing international movement that was kicked off worldwide by inspiring and dynamic projects such as those created by Ibuku and Bamboo U. These examples have opened our eyes to the value of bamboo as a potential luxury material, developed an innovative curvilinear design aesthetic, and encouraged us to question our construction conventions. Despite these benefits, most of these designs remain a challenge to consider for temperate climates with cold winters, hot summers, and a variety of other non-tropical climatic conditions. In addition, due to the limited supply of timber bamboo in temperate regions, building with bamboo is an expensive endeavor, that only a few select clients could afford, even if one can overcome regulatory barriers.

Aesthetics aside, technically speaking, a timber bamboo pole is fast-growing, easy to process, and grows naturally in the structurally optimal form of a long linear tube. Furthermore, according to the Technical University of Delft report, Bamboo in the Circular Economy, the growth of bamboo sequesters more carbon than a boreal forest. In addition, if the bamboo waste is burned when the building is demolished, it will create more energy per unit of carbon emission than fossil fuels, making bamboo carbon negative over its entire material lifetime.

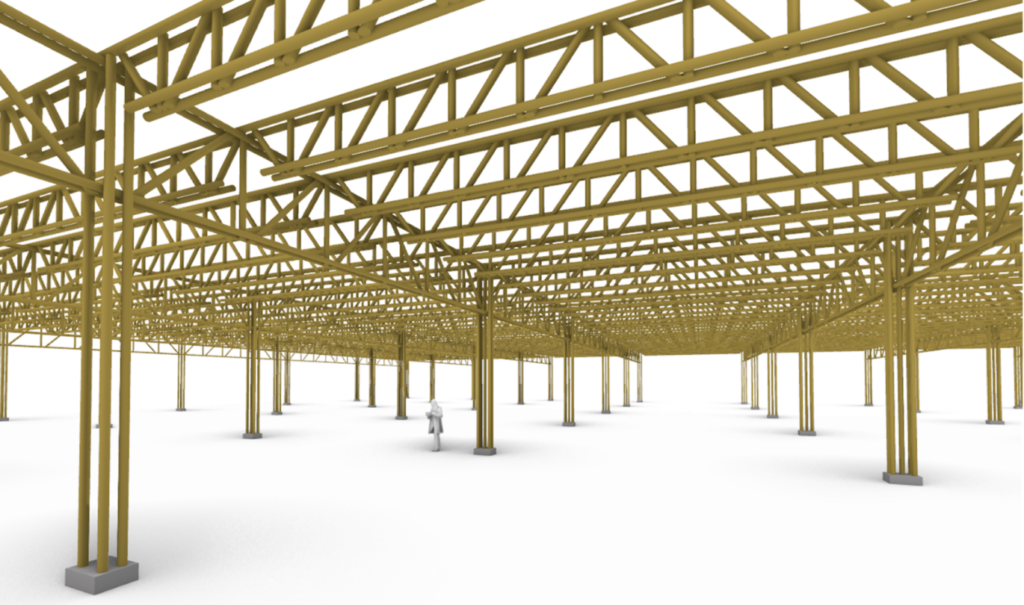

According to the International Energy Agency (IEA) 2019 report, 11% of total global CO2 emissions come from steel, concrete, and glass manufacturing. In the US alone over twenty thousand storage facilities, agricultural structures, box stores, and commercial “box” buildings are constructed each year from millions of tons of high-carbon conventional steel and aluminum. Simple long-span steel trusses are commonplace commercial structural solutions using these materials.

Could we harness the environmental and structural benefits of bamboo timber to construct standardized trusses for these conventional commercial box buildings? If implemented at scale the result would reduce the carbon footprint of the building sector, create carbon credits to be sold, and boost the demand for bamboo production as a new conventional sustainable architectural material on every continent.

Design and Construction of the Bali Bamboo truss

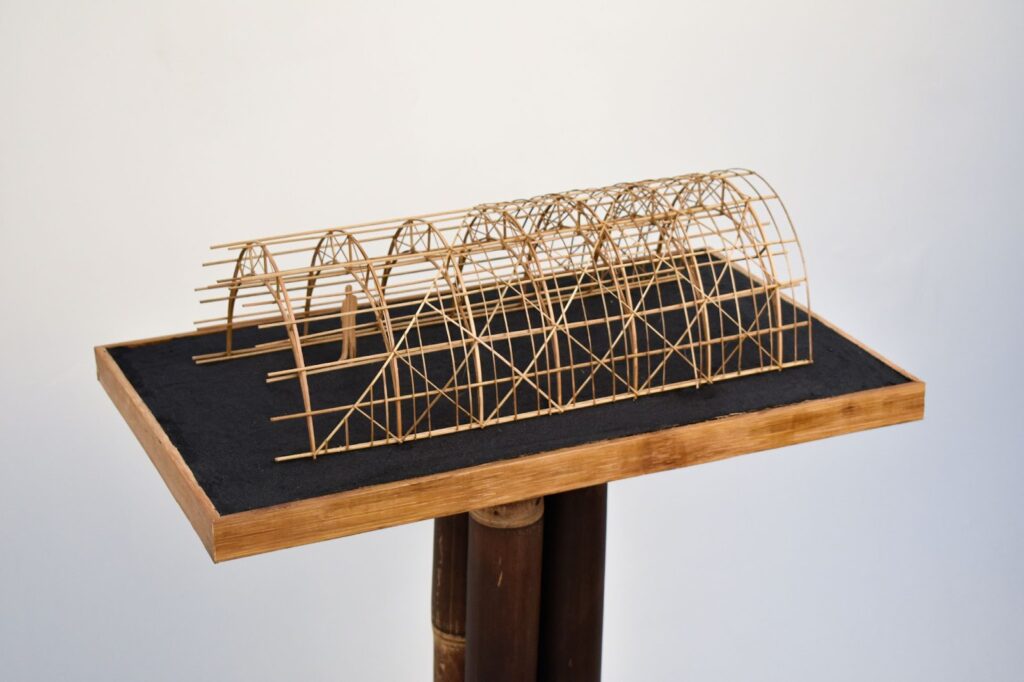

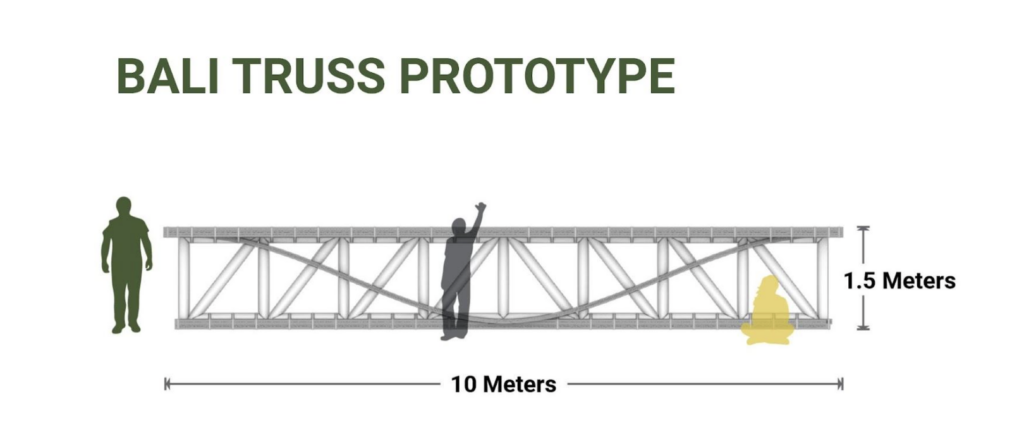

On the campus of Bamboo U in Bali, Indonesia, in collaboration with Washington University in St. Louis, USA we experimented to investigate the potential of standardized bamboo trusses for use in commercial box buildings. We designed and built a 10-meter bamboo truss built from bamboo poles and splits, and tested the construction to failure.

The overall design of the Bali Bamboo truss is based on a standard Howe truss, placing the internal diagonal web members in compression supported by two tensile catenary beams flanking both sides.

An essential factor for trusses is joinery since they are built of parts that are shorter than the overall span. To design joints for a bamboo truss several factors need to be considered.

Bamboo has incredibly high tensile and compressive strength. While we often manufacture steel or aluminum structural members into long cylindrical tubes, bamboo grows naturally in that form. On the other hand, bamboo is comparatively weak in shear, meaning careful attention in needed in designing connections to prevent them from splitting.

For the Bali Bamboo Truss, we explored means to connect the many parts without having to drill holes into the bamboo poles. To do this, we opted to use bound bundles of splits) to build the upper and lower chords of the truss. The bundles were held together by high-tension stainless-steel bands secured every 50 cm along the length of the chord. This allowed the interior diagonal and the vertical member of the truss to be connected by compressing them together rather than through fasteners that require drilling holes. Finally, the catenary curves were made of splits (Dendrocalamus asper) which were attached to the upper cord of the truss using a wedge-shaped tenon and bound with steel clasps.

The final truss was 10 meters long and 1,5 meters in height. We spent about three and a half days with a team of five people assembling the truss. The process started by Brad nailing stacks of bamboo splits together and layering these splits into larger bundles which were bound with 1 inch wide stainless steel bands. The vertical poles were pegged through the split bundles to carry a nominal amount of tension, intended only to hold the truss together during assembly. After completion of the truss, we set it on two foundations made of blocks and prepared for our in-situ load test.

Load Testing and Results

To test the truss, we piled 12-kilogram blocks on the top chord one at a time distributed across the middle third of the span. After every ten blocks (120 kg) we measured and recorded the vertical displacement of the truss. We intended to load the truss to failure.

As we loaded the truss the vertical displacement occurred in non-linear increments, suggesting it was non-elastic bending. At 528 kg of load, the upper cord began to buckle horizontally which began to destabilize the entire construction as it twisted. This kind of loading would not normally occur in a roof truss, as it would be typically stabilized by the roof deck itself. In response, we unloaded the truss, and stabilized it horizontally with tension cables for further vertical loading, to better understand its legitimate true potential.

When the load was removed the displacement was not recovered, suggesting that most of the bending to that pint was due to settling of the joints rather than due to elastic loading.

We continued to load the truss 12 kg at a time along the middle third of the span. This resulted in some asymmetrical loading of the truss. At 1,350 kg failure occurred in the joint between the seventh vertical pole from the left and the lower chord. The bamboo pin installed there, a pin that was intended only to carry tension during construction sheared through, causing a sudden and catastrophic failure throughout the truss.

Findings and Areas of Improvement

While we did not reach our desired goal of carrying 3000 kg without failure, the process of constructing the truss and the specific way it failed was highly instructive.

Key points learned from the construction of the Bali Bamboo Truss:

- The construction process using bundled bamboo splits was highly work-intensive and not easily converted into a repeatable process.

- The use of fish-mouth joinery and angled compression joints in the vertical and diagonal poles was highly work-intensive and difficult to ensure tight-fitting joints that transferred the load evenly

- The installation of the high-strength stainless steel bands is cumbersome and needs development. In addition, the extensive amount of use of steel diminishes the benefits of the low carbon footprint of the bamboo poles.

- Compared to prior bamboo truss experiments the Bali Bamboo truss was much heavier and more difficult to move without heavy equipment.

Key Points Learn from how the loaded Bali Bamboo truss structurally failed:

- While the truss was designed for the verticals and diagonals to be placed in compression when loaded, the vertical elements do carry a certain amount of tension when loading in non-symmetrical, as learned from the means of failure. These joints could be easily reinforced with steel threaded rods or long continuous steel bands dramatically improving the structural capacity. Although, this extensive use of steel diminishes the benefits of the low carbon footprint of the bamboo poles.

- The non-linear incremental deflection of the truss, due to the settling of the split bundles and the compression joints, was a permanent distortion, rather than being elastic. If this method is to be further explored, pre-loading the bundles, or building the truss with a designed camber before installation is needed to be considered.

- The catenary curve helped reduce deflection before catastrophic failure. Improving the connections at the upper chord could greatly improve their performance

Future Areas of Improvement

The tension joints of the bamboo truss continue to be the limiting factor for design and performance. Considering a means to spread the shear forces produced by joints in tension, combined with a means to prevent and limit the poles from splitting is necessary for future exploration to improve truss performance.

Overall, this experiment was highly helpful in improving our understanding of standardized bamboo truss design from several aspects including speed of construction, optimization of joinery, and improvement of overall strength from previous tests by over 20%. While we are getting closer to achieving our goals, the next steps include a series of focused testing for improved tensile joinery.

We hope that within the next year, we will have a functioning prototype of a bamboo truss that could be considered for use in a pilot project to construct a large-scale box store or warehouse in the US.

Wyly Brown NCARB, AIA, ByAK, is a professor of architecture at the Washington University in St Louis and a founding partner of the international architectural practice Leupold Brown Goldbach Architekten. He has spent the past five years researching bamboo as an environmentally sustainable architectural material for use in temperate regions such as the United States and Europe.

OCTOBER 10-21, 2025

The 11 Day Bamboo Build & Design Course in Bali

In 11 days, we'll show you how to build bamboo structures we’ll share all that it takes to build with nature.

Start Anytime

The Bamboo Harvesting Course

The Bamboo Harvesting Course is an online step-by-step training to harvest and care for your bamboo clumps to ensure their longevity and productivity. This maximizes the potential of this beautiful grass as a rapidly renewable resource.Whether you are an architect, builder, or sustainability enthusiast, this mini course will enable you to utilize this rapidly regenerative resource as a durable construction material.It will help remove any fear or doubt about the durability of bamboo and help you build reputable bamboo structures that stand the test of time!