How We Built An Amazing, Low-cost Bamboo And Mud Yurt

By Mia Larsen | June 15, 2023 | Bamboo U Built Projects -

Despite its humble nature, mud is an easily accessible resource that has proven its resilience over centuries in civilizations across the globe.

In our pursuit of a sustainable future, we often prioritize new technological advancements as the path forward, overlooking the wisdom of time-honored construction techniques. Bamboo is often disregarded around the world as a poor-man’s timber and earth building is looked at in a similar way. When maintained and thoughtfully designed, earth buildings have demonstrated remarkable longevity, enduring for several decades or even centuries.

Mud, being an ubiquitous natural material, is readily available in abundance across many regions of the world. Its availability makes it an ideal choice for low-cost construction projects, by reducing transportation costs and carbon emissions that occur when materials are sourced from distant locations. However, it is important to acknowledge that earth building techniques can be labor-intensive. Therefore, when you are not doing the building yourself and labor is a component of the project cost, it is crucial to account for this factor in the overall assessment.

One of the most compelling reasons to embrace mud as a construction material is its inherent sustainability. Mud is biodegradable and poses no harm to the environment when disposed of properly. The process of manufacturing conventional building materials such as concrete or steel involves high energy consumption, leading to substantial carbon emissions. Mud however, requires minimal energy input, as it is primarily sourced from the earth, resulting in a significantly lower carbon footprint.

Not only is earth building carbon neutral, it possesses excellent thermal properties, making it an ideal choice for maintaining comfortable indoor temperatures in both hot and cold climates. Its high thermal mass allows it to absorb heat during the day and release it gradually during the night. This reduces the need for artificial heating and cooling systems. When combined with bamboo, which possesses lower thermal conductivity, earth building emerges as an ideal complementary material.

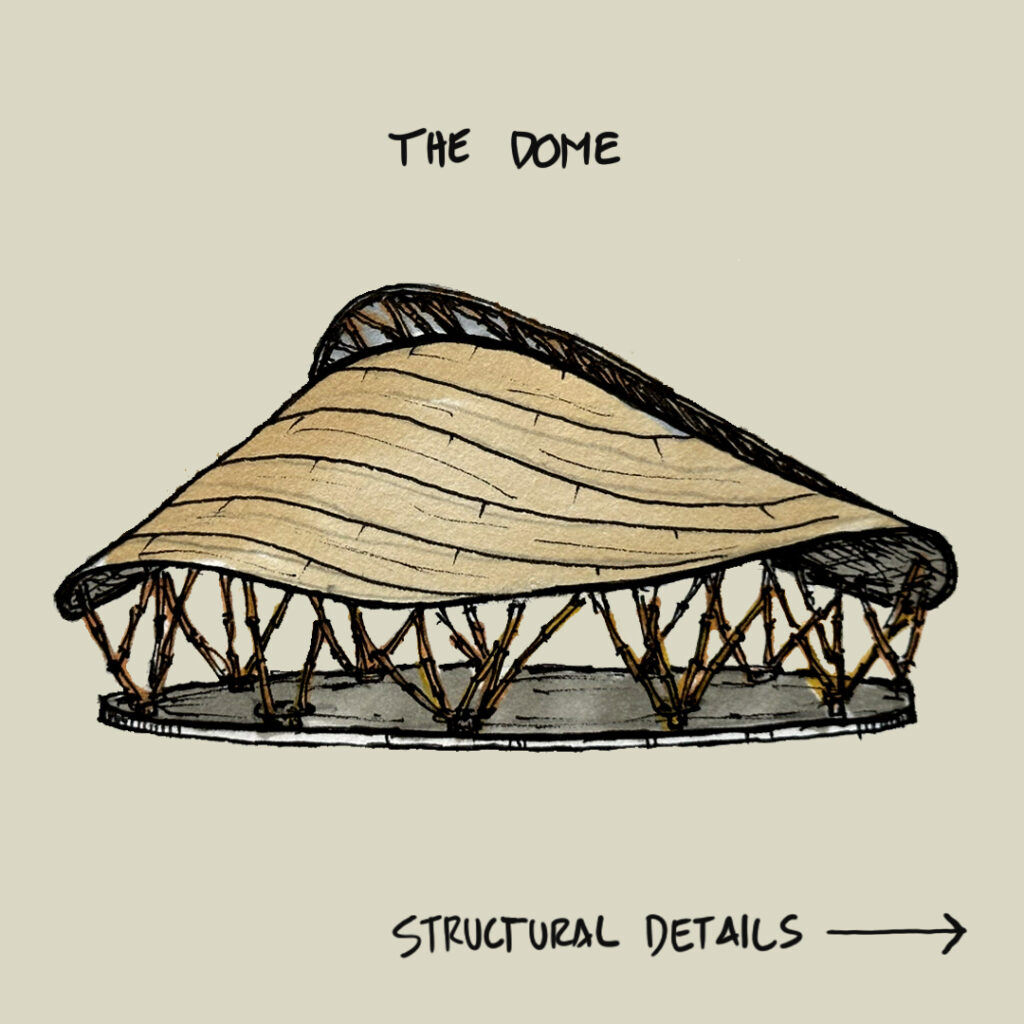

In the November 2022 and the March 2023 Course at Bamboo U here in Bali, we constructed two yurts made from bamboo and mud. Here is a summary of the process we undertook to construct these low-cost bamboo yurts.

In this article, we’ll be sharing details on the following:

- Building Foundations

- Installing Frames and Rafters

- Building The Walls

- Installing The Door

- Building The Roof

- Finishing Elements

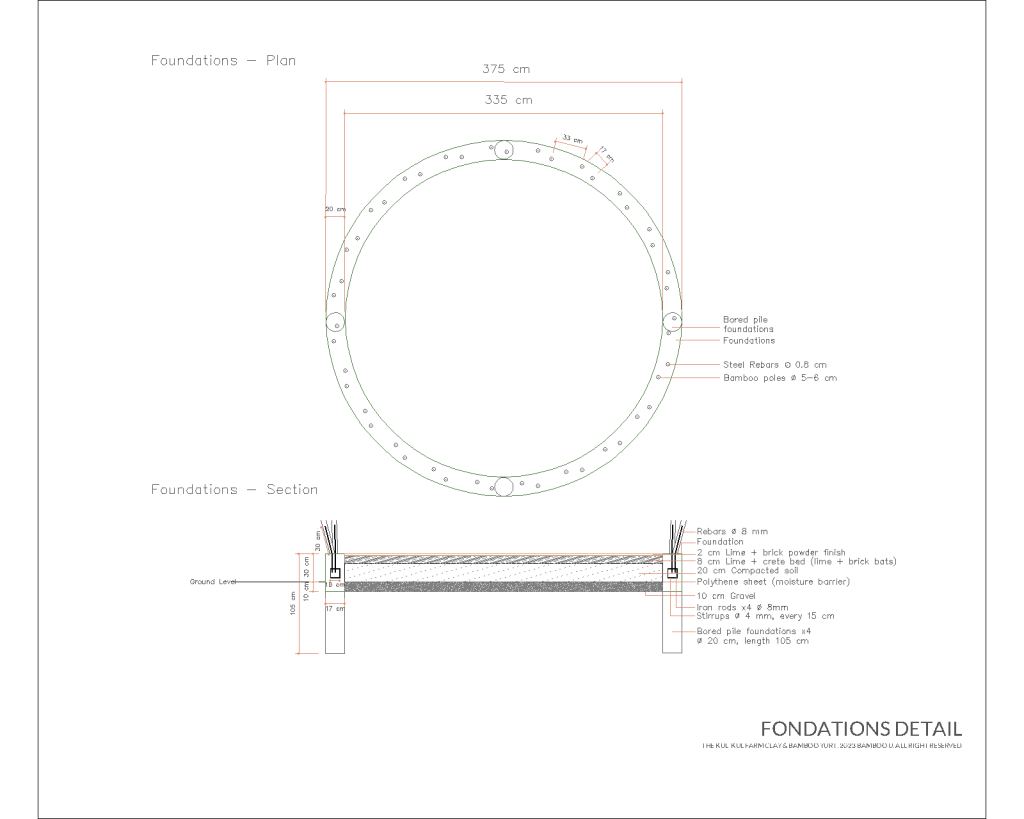

Building Foundations

The construction process of the bamboo and mud yurt began with laying the foundation. Our carpenters poured a ring foundation and four bore pile foundations were laid, with rebars added to fix the bamboo poles in place. After the ring beam and oculus were made from laminated bamboo, they were supported in place by scaffolding.

Installing Frames and Rafters

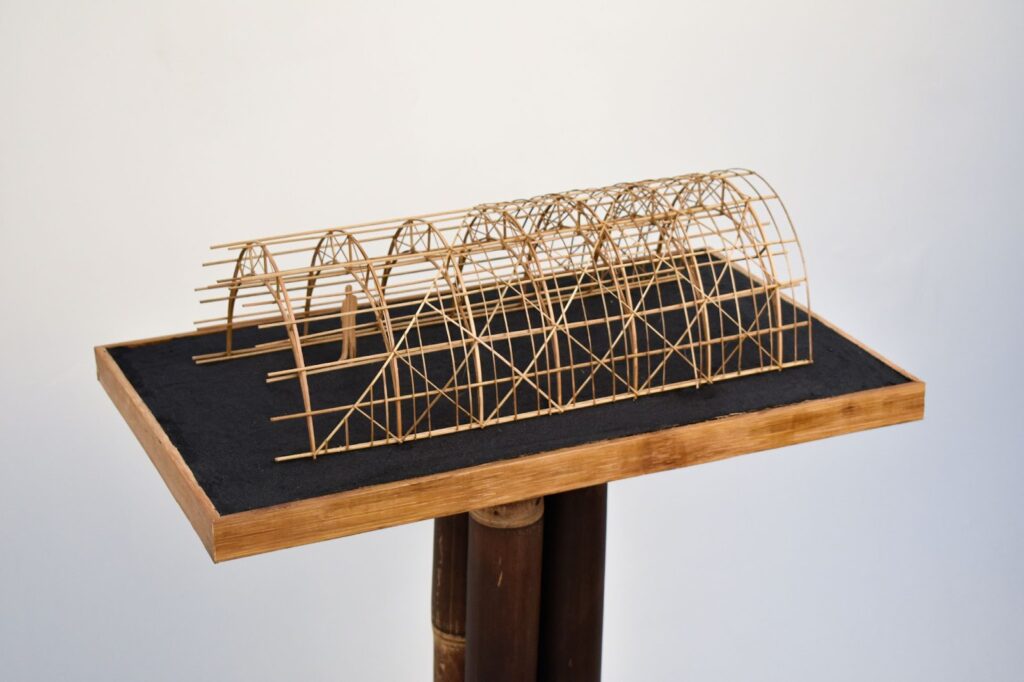

With the foundation in place, students began to build the frame of the yurt. Bamboo poles were selected and cut to size, with measured markings to indicate intersection points. Assisted by scaffolding, the poles were dropped into position from above onto the rebar and the structure was temporarily fixed along the ring beam.

Holes were drilled through the bamboo poles and ring beam and all intersecting poles were fixed with bamboo pins and excess trimmed. Where the ring beam and the wall poles met they were fixed with a combination of bolts and pins. In instances where there was a gap between intersecting poles requiring drilling and bolting, a rope tourniquet, also referred to as a butterfly knot, was used to bring the poles flush together. For cases where a gap still persisted, a small piece of bamboo was inserted into the gap, and then the poles could be drilled and bolted together to create a firm connection.

To add the rafters, bamboo poles were laid between the oculus and the ring beam.

The inner layer of bamboo rafters were connected first followed by the outer layer, and then all the points where the rafters crossed were drilled and bolted together.

Building The Walls

To create a base to hold the mud wall at the desired angle, bamboo splits were woven between the poles of the wall structure in a similar way to basket weaving. We then began to make a cob mix using our feet to combine the sub-soil, sand and water. To enhance the strength of the cob, a mixture of bamboo sawdust and coconut-chopped rice straw was added.

It is important to note that the specific ratio of these components is dependent upon the type of soil being used. Testing the ratios of clay, sand, and silt in the soil you plan on using for earth building is essential, as any miscalculations can lead to potential issues such as cracking, improper drying of the wall, or compromised structural integrity. In the case of the rich clay soil we have in Bali, our typical cob mixes consist of three parts sand to one part clay. However, it is imperative to adapt this ratio depending on the specific composition of the soil available.

Once we had the cob mix we began to fill the cavities between and over the top of the bamboo weave. Decorative eye-shaped holes were left in the wall and bamboo lidi was tied in place to indicate the curves of the top of the wall. Lidi in Indonesian means stick, a bamboo lidi however is a long, very thin piece of bamboo carved from a bamboo pole. We continued weaving bamboo splits and filling them up with cob up until this line.

Installing The Door

An oval door was made using laminated bamboo strips, slices of bamboo, banana paper, and glass at our factory. Because of the angle of the wall of the yurt and its curve, the installation of the door posed a challenge. We cut the bamboo poles back bit by bit where the door would be placed, and with a few adjustments and the addition of more bamboo above the door, we managed to lift the door in place with a big team effort and secure it.

Building The Roof

The next step involved the creation of a long lidi bundle, which would encircle the perimeter of the rafters, providing structural reinforcement and support to the roof.

A lidi bundle is formed by bundling a number of lidis together. Lidi bundles possess excellent flexibility, allowing them to bend easily. Consequently, they serve as an ideal choice for edging roofs and forming curved and organic shapes.

Once the lidi bundle was assembled, it was lifted into position and secured onto the eave of the rafters using bamboo pins. To optimize natural light within the yurt, a grantangan roof detail was incorporated. This involved the manual carving of angle joints, reminiscent of fish mouth joints, onto the ends of 48 poles using traditional Balinese knives called mutiks. These were then fixed into their designated positions on each rafter, allowing the roof's edge to gracefully uplift.

Finishing Elements

After the main construction was completed, the carpenters added alang-alang along the roof, a skylight above the oculus, some curved stairs, and a bench complete with a shoe rack. They also added the final layers to the cob wall. The first layer to be spread over the cob is called a brown coat mix, consisting of a ratio of 2:1 sand:clay plus two-thirds bamboo sawdust. This was followed by an Otsu mix, which is a traditional Japanese plastering technique. This mix comprises 3:1 clay to lime plus sieved bamboo sawdust. The floor was also completed, with a layer of gravel, DPC polythene sheet, and compact soil with a final layer of lime and brick powder, which was smoothed over, polished, and left to dry for five days.

Witnessing a structure take shape from locally harvested bamboo poles and earth walls crafted from on-site collected mud evokes a profound sense of satisfaction. Similar to bamboo, mud holds immense promise as a sustainable material of the future.

If you want to learn more about building with mud and bamboo join our upcoming in-person course!

Mia is an architectural designer from Australia with hands-on experience in bamboo building. Her passion for design, fueled by a deep desire for sustainable solutions, led her to join the Bamboo U team as a Student Visitor from March-August 2023 and as a content writer from 2025.

JUNE 13-24, 2025

The 11 Day Bamboo Build & Design Course in Bali

In 11 days, we'll show you how to build bamboo structures we’ll share all that it takes to build with nature.

Start Anytime

The Bamboo Harvesting Course

The Bamboo Harvesting Course is an online step-by-step training to harvest and care for your bamboo clumps to ensure their longevity and productivity. This maximizes the potential of this beautiful grass as a rapidly renewable resource.Whether you are an architect, builder, or sustainability enthusiast, this mini course will enable you to utilize this rapidly regenerative resource as a durable construction material.It will help remove any fear or doubt about the durability of bamboo and help you build reputable bamboo structures that stand the test of time!