What Properties Make Bamboo an Excellent Material for Construction?

By Inaara Thawer | June 21, 2024 | Exploring Bamboo -

Using bamboo for building dates back millenia. As a result of its unique macroscopic and microscopic qualities, it is a versatile construction material.

Bamboo has been used for thousands of years as a construction material. It is optimal for construction due to its physical properties that allow it to be strong, yet remain lightweight. To understand how versatile bamboo is for building, we must understand how it works as a plant.

In this article we dive into the following:

- Bamboo on the Macroscopic Scale,

- Bamboo on the Microscopic Scale, and

- Bamboo as a Composite Material

By understanding what bamboo looks like on both the macro and micro scales, we can understand the nature of bamboo as a strong and flexible natural composite.

Bamboo on the Macroscopic Scale

Rhizomes and Culms

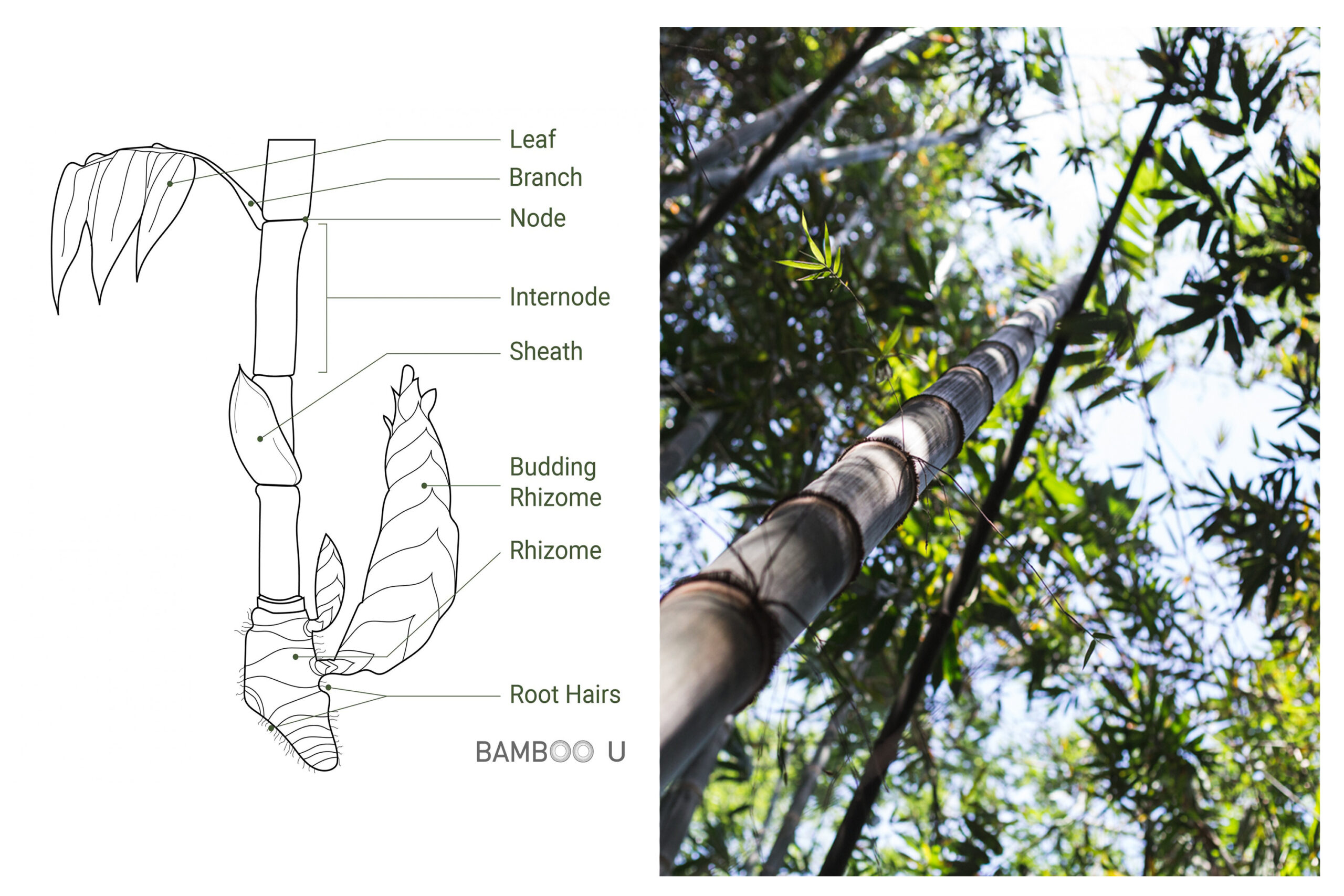

One of the bamboo plant’s key features on a macro scale is its underground system. This is known as the rhizome network. Rhizomes are key organs of the bamboo and are responsible for producing the energy needed to grow bamboo poles.

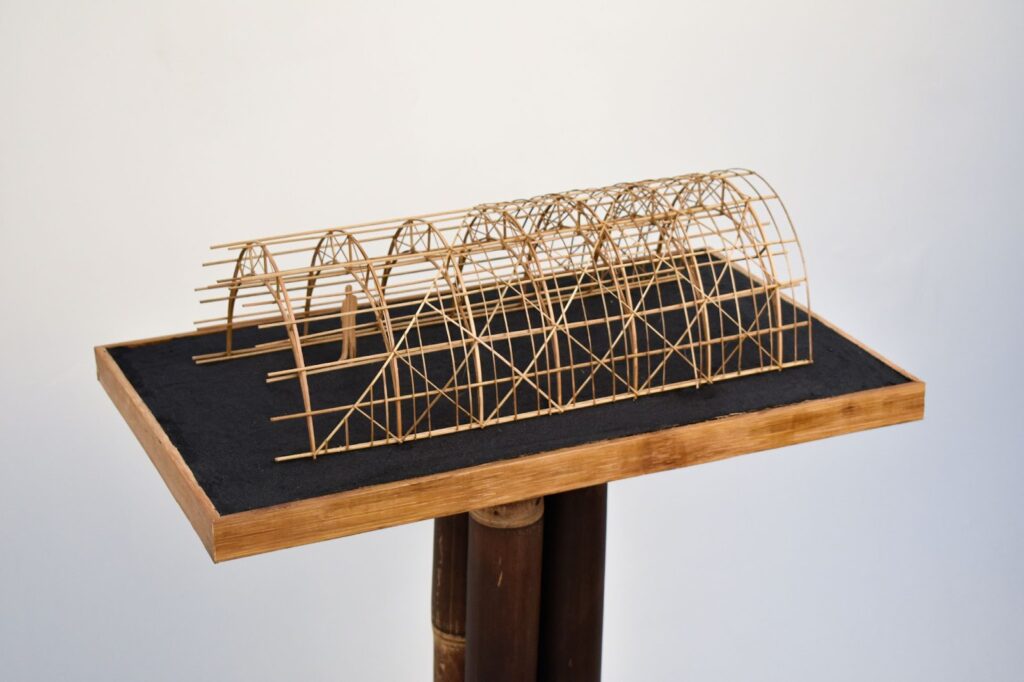

The bamboo poles, or culms, branch upwards out of the ground from the rhizome network. These take between 6-9 months to grow to their full height, which can reach up to 30 meters tall depending on the species. When used in their round pole form, the bamboo culms are excellent structural members for buildings.

The culms have a thick, colored skin, known as the epidermis. This is one of the key elements that give bamboo its strength. It is high in silica and enhances the strength and durability of the poles.

Nodes and Branches

On the culms, we can see horizontal bands, where the bamboo swells outwards slightly. These are called nodes and the space between each node is referred to as the internode. Nodes are part of what makes bamboo very strong. This is primarily due to the plant’s microstructure in these areas, which will be discussed in the following section.

Growing off the nodes, one can see branches and leaves. The leaves are responsible for fueling the plant with energy. They convert sunlight into chemical energy through the process of photosynthesis.

Now that you have an overview of how the plant works on a macroscopic scale, let’s dive into how it works on a microscopic scale.

Bamboo on the Microscopic Scale

While the macro scale is important, by understanding bamboo on the micro scale, we can truly understand why bamboo is so impressive for construction. These smaller components of the plant are what provide the material with its impressive structural qualities.

Within the bamboo poles, there is the fibro-vascular area. This is made up of two main parts - the vascular bundles and parenchyma.

Vascular Bundles

The vascular bundles provide bamboo culms with strength and rigidity, while simultaneously transporting nutrients and energy across the length of the pole. They are composed of bamboo cellulose fibers and vascular tissues.

The fibers inside the culm run longitudinally and extend up the full length of the pole. They play a key role in determining the bamboo’s strength and elasticity. They wrap around vascular tissues, to form the vascular bundles, which are key components of the plant’s internal structure. In fact, it is these fibers that make bamboo incredibly lightweight and strong, with a high strength-to-weight ratio that surpasses that of steel!

On the other hand, vascular tissues are long, tubular tissue structures within the culm. Like the bamboo fibers, they stretch up to the full height of the bamboo from the ground level. They bring water and nutrients up from the rhizomes to the leaves and photosynthetic energy down from the leaves to the rest of the plant.

Parenchyma Tissue

In the space between the vascular bundles, there is the parenchyma. This is the tissue that holds the vascular bundles together within the culm.

In a cross section of bamboo, vascular bundles are visible as small pores. The density of these “pores” increases towards the tough outer skin, or epidermis, of the bamboo. This indicates that there is increased strength towards the outer wall of the pole.

While the vertical fibers and tissues stretch the entire length of the pole, there are instances where they cross horizontally. This is at the nodes. At these points, the fibers intertwine within the poles to form disks called diaphragms. These provide internal bracing for the culm at regular intervals which therefore enhances its overall rigidity and strength.

As the bamboo matures, these vascular bundles and parenchyma become lignified. Lignin is the substance that makes wood rigid. In bamboo, the lignin grows around the bundles and parenchymal tissues to make them firm and rigid. Around 4 years of age, this lignification process makes the bamboo culms perfect for construction and ideal for harvest.

Bamboo as a Composite Material

Since bamboo is made up of two key components on a microscopic scale, it is referred to as a natural composite. It can be compared to man-made composite materials such as carbon fiber and resin, or rebar and concrete. In composite systems, one of the elements gives the material its strength, while the other keeps everything in place. In bamboo, the vascular bundles give the material its strength, while the lignin and parenchyma hold these elements in place.

The internal structure provides the culms with excellent flexural properties. One such example of this was during the 7.8-magnitude earthquake that occurred in Ecuador in April 2016. Over 1200 buildings were destroyed in this natural disaster, while over 35,000 were classified as unsafe or only for limited use. However, according to a study by researchers at the International Bamboo and Rattan Organization (INBAR), many well-built bamboo structures in this region were able to withstand the earthquake’s tremors. This indicates that bamboo can be useful for building disaster-resistant structures, particularly in seismic-hazard zones.

References

Base Bahay Foundation. (2023b, April 14). BAMBOO AS A CONSTRUCTION MATERIAL IN EARTHQUAKE-PRONE AREAS. Base Builds. https://base-builds.com/2023/04/14/strongbamboo-as-a-construction-material-in-earthquake-prone-areas-strong/

Van der Lugt, P. (2017). Booming Bamboo. Materia Exhibitions BV.

Van Drunen, N., Cangás, A., Rojas, S., & Kaminski, S. (2016). Post-earthquake Report on Bamboo Structures and Recommendations for Reconstruction with Bamboo on the Ecuadorian Coast. International Bamboo and Ratan Organization. Retrieved May 5th, 2024, from https://www.inbar.int/resources/inbar_publications/post-earthquake-report-on-bamboo-structures-and-recommendations-for-reconstruction-with-bamboo-on-the-ecuadorian-coast/

Inaara is an architectural designer born and raised in Tanzania. With her passion for green building systems and bio-based materials, Inaara's work combines her love for sustainability, design, research, and education. She is currently the Online Coordinator/Head of Content at Bamboo U.

JUNE 13-24, 2025

The 11 Day Bamboo Build & Design Course in Bali

In 11 days, we'll show you how to build bamboo structures we’ll share all that it takes to build with nature.

Start Anytime

The Bamboo Harvesting Course

The Bamboo Harvesting Course is an online step-by-step training to harvest and care for your bamboo clumps to ensure their longevity and productivity. This maximizes the potential of this beautiful grass as a rapidly renewable resource.Whether you are an architect, builder, or sustainability enthusiast, this mini course will enable you to utilize this rapidly regenerative resource as a durable construction material.It will help remove any fear or doubt about the durability of bamboo and help you build reputable bamboo structures that stand the test of time!