Building Bamboo Walls with Mud and Lime

By Sai Goutham | June 15, 2022 | Construction -

The combination of bamboo and lime/mud is an amazing building technique to build walls for bamboo buildings that can be thinner, lightweight, flexible with shapes, beautiful, and also can be built faster.

Building mud and lime walls along with bamboo or wooden laths is a building method that has been used in different parts of the world from ancient times. This technique has been used traditionally in England; called wattle & daub and a similar technique in South America is referred to as bahareque. Bamboo, wood, or reeds were used as the structural frames whilst lime or mud was used as a filler material to seal the walls. Today is also called the lath and plaster technique.

This technique to build walls for bamboo buildings is efficient because the walls are thin, lightweight, and flexible and they can be built relatively quickly.

In this article, we share the 3 things to consider when building mud, lime, and bamboo walls for bamboo buildings.

- Building The Bamboo Wall Frame

- Preparing And Applying The Sealer

- Finishing

1. Building The Bamboo Wall Frame

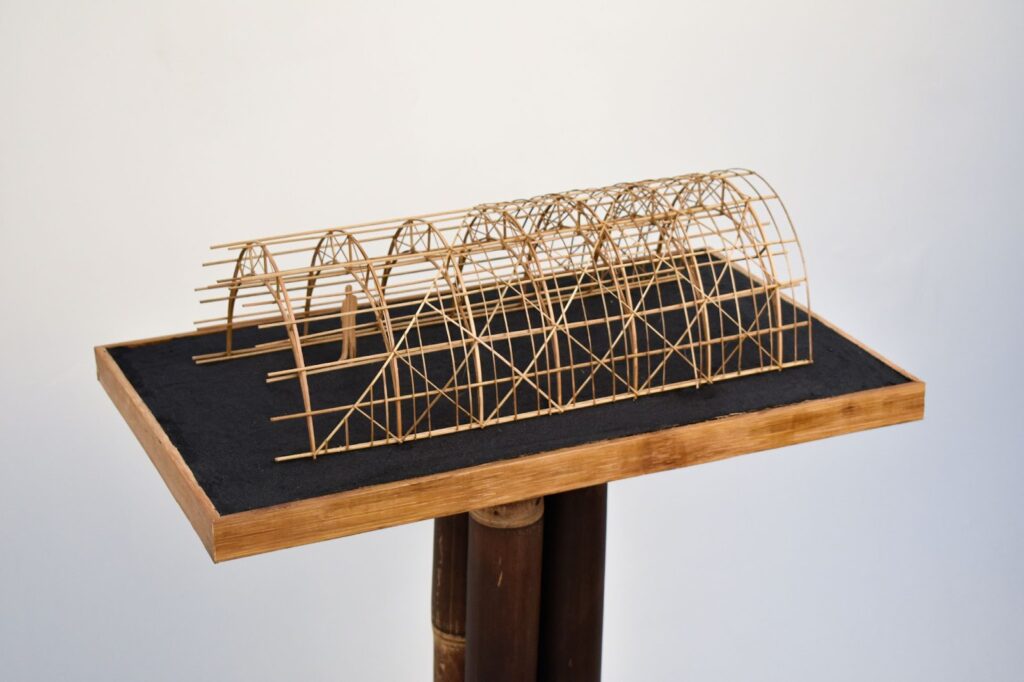

The first step is to build a wall frame using bamboo, which will support the mud mixture on both sides. Due to bamboo’s flexibility, it allows us to craft walls of playful shapes, forms, and patterns with any desired length and height.

The best way to build the frames is by weaving. Different types of processed bamboo materials can be used depending on the desired shape, form, and pattern of the wall. The best bamboo material to use is either flattened bamboo, locally known as peluhpuh in Bali, or bamboo splits because they are easy to work with to build the wall frames.

2. Preparing and Applying The Sealer

The sealer is the sticky coating that is used to cover the bamboo framing to render the wall hard and solid.

The sealer can be prepared using mud or lime:

a. Mud Mixture

The mud mixture consists of subsoil, water, and organic fibres. It is very important to select the right soil for construction and if possible it is best to source the soil from the construction site itself.

Clay, silt, and sand are the main contents for subsoil. The mud mixture should have a balance of binder (20-30%), and aggregates (70-80%). Clay is a binder that helps to hold the sand and fibres together. The sand acts as an aggregate that gives compressive strength whilst the fibres add tensile strength to the mixture. Straw, rice husk, animal dung, coconut coir, and jute are a few of the natural fibres that have been used traditionally depending on local availability.

Naturally, subsoil content varies so try to find the right clay: sand ratios in the soil before preparing the mixture. This can be done by a simple jar test. From the test results, you will be able to modify your soil by adding clay or sand. Making samples and test batches beforehand helps to ensure you have the right balance of mixture before beginning.

Now it is time to physically work the mixture, traditionally hands and feet are used to mix, and we have found that to be the best way to mix and aerate at the same time. Add water as needed and mix uniformly.

After the mud mixture is prepared, divide the mud mixture into smaller chunks. This helps to ensure that the mud mixture has been worked evenly. Sometimes it is hard to achieve overall uniformity in the mixture but this way the mix quality is improved right away. Small chunks are also easier to pass/carry on a construction site.

Now it’s time to apply the mud mixture to the woven bamboo wall frame. The best practice of application is 3 layered coats. The first layer is made by applying the mixture roughly on both sides of the walls at the same time by hand. Because clay tends to shrink when it dries, the rough application will help to hold the mud mixture well to the woven bamboo surface and results in minimal cracking. Applying the mixture on both sides helps to reduce the movement of the woven bamboo frame which results in greater wall stability in the long term.

The second coat application is to level the first layer, it helps to fill the cracks and render the wall surface levelled for the smooth finishing layer. Use only small fibres or no fibres for this layer. For rustic and rough-textured walls, this can be the final layer.

The third coat application is the final layer, where a thinner layer of mud and sieved sand mix is applied without adding any fibres. This helps to achieve a smooth finish.

b. Lime Mixture

Lime mixture is another option to use with bamboo laths to create natural walls. Using lime requires more skill and craftsmanship to build. It is important to study and understand the local availability of lime sources and the kind of lime available to build locally.

Lime mixture contains slaked lime and aggregates such as river sand, stone dust, or burnt brick powder. Begin by making small samples first and check the results before applying them to the walls to find the right mix.

In a few of our projects at Bamboo U we used slaked lime, a burnt brick powder and water to seal the bamboo framed walls. We use 1 part lime, 3 parts burnt brick powder and just enough water to bind the lime. We used this same mixture both for the base layer and the levelling layer. For the final finishing layer we use 1 part lime, 2 parts of very fine burnt brick powder to ensure smooth finish.

3. Additional Wall Finishes

It is always challenging to achieve desired colour finishes but using pigmented lime washes and clay paints it can be possible

The combination of bamboo and lime/ mud is an amazing building technique to build walls for bamboo buildings that can be thinner and lightweight but remember these are limited to only non-structural partition walls, and it is advisable to avoid hanging heavy objects and furniture onto these walls. If these walls are used as the building's exterior walls, it is very important to have a good overhang on the roof to avoid elements like rain and direct sun over the walls. These walls require less maintenance, they need to be mud-plastered/lime-washed every 4-5 years. These walls can last more than 20-25 years if maintained properly.

Sai joined the Bamboo U team in March 2020 as Research & Development Manager. He is also a natural builder and an architect from India. He has managed many mud and bamboo projects over the years.

June 7-18, 2024

The 11 Day Bamboo Build & Design Course in Bali

In 11 days, we'll show you how to build bamboo structures we’ll share all that it takes to build with nature.

April 26, 2024

The Fundamentals of Building with Bamboo Online Course

All the fundamentals you need to get you started working with bamboo. Deep dive into cinematic videos and step-by-step guides that will provide you with a strong understanding of bamboo as a design and building material.