Preparing And Selecting Your Bamboo On-Site For Construction

By Cécile Durand | October 1, 2021 | Construction -

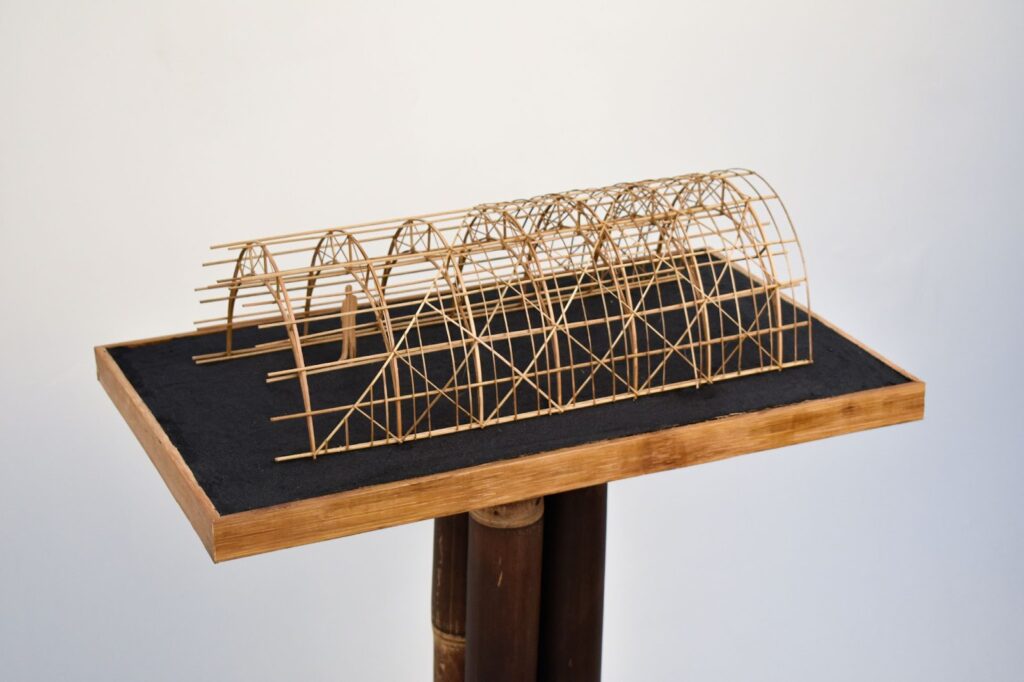

After weeks of designing, model making and planning, you are ready to begin the construction phase of your bamboo project. It is now time to get some bamboo, bring it to your site and start placing it into your structure. And though breaking ground on a bamboo project is a very exciting moment, it can also feel overwhelming to see all of your bamboo arriving on site and not know how to select the right piece for a specific part of your design.

Ideally, when your bamboo arrives on site, it is already mostly ready for construction. This means that it is the right species, it has been harvested at the right age and also treated correctly to avoid future structural complications. Your responsibility now lies in choosing the exact piece that will become the future column or beam in your project. This can feel a little intimidating, especially if it is your first time working with bamboo in a construction project.

This is why we believe preparing your site and materials for construction before setting your bamboo into place is crucial to successfully running your project’s construction phase. Once completed, a strong setup will organise all your material on-site and save you time so you can quickly find the ideal bamboo pole as soon as you need it.

During our Bamboo Online Immersion, we dedicate a section of the course to bamboo selection because we really do think that it is an essential step in building beautiful and strong bamboo structures. This article breaks down the steps for preparing and selecting the right bamboo on site. We find that there are 3 key steps to run your construction site efficiently and successfully:

- Best practice to store your bamboo on-site.

- Check the quality of the bamboo you received on-site.

- Selecting the right bamboo for construction.

1. Best practice to store your bamboo on-site.

When your bamboo arrives on site, it will most likely be moved from the back of a truck onto the ground. Therefore, before your bamboo is shipped to your site, it is essential that you have already prepared a place to store your bamboo whilst it waits to be used in your structure. This does not need to be a fancy shelter, only a place where the bamboo can be protected from the natural elements and the moisture in the ground. If you do not do this, your bamboo will start rotting before you even use it in your design.

To keep your bamboo in the best shape possible throughout the construction process, there are a few factors to consider when you are storing your bamboo poles.

- Bamboo only likes the rain and the sun when it is actively growing in the soil. Any other time, it prefers to stay away from direct sunlight and the rain. Wherever you decide to store your bamboo on your construction site should therefore be well protected from the rain and the sun. A taut tarp or corrugated steel panels are cheap and easy to set up solutions if you do not have a specific shelter for your bamboo. If you need some inspiration on how to build a cheap yet durable bamboo shelter, you can check out our other article about our ARS Bamboo Shelter here.

- To prevent your bamboo from getting mouldy, best practice is to keep the poles vertical and off the ground. When bamboo poles are laid down, one side is constantly facing the ground which keeps all the moisture to one side. In the long run that can lead to fungus build up and blemishes to appear on the bamboo which will be both less pleasing to the eye and potentially harm the bamboo’s structural integrity. When they’re held up vertically, the poles are ventilated constantly which prevents moisture and fungi from building up.

- As best as you can, you should try and organise your poles according to species, portion of the pole and size. This is less to do with having better poles for construction but more to do with saving you and your team considerable time throughout the building process. If your bamboo is well categorised, then you simply have to go through the stacks of the right species and dimensions to find the one that you need. Ideally, this organisation is done every time you receive some new bamboo on-site.

2. Check the quality of the bamboo you received on-site.

A big reason why bamboo is both so fun and difficult to work with is that bamboo comes in all shapes and sizes, regardless of species, location and harvesting method. Two bamboo poles from the same species, or even from the same clump, will not be identical. The bamboo that you receive will therefore most likely look like a pile of many different poles, all somehow different and similar at the same time.

The first thing to do is to check the quality of the bamboo you have received. The most obvious reason behind this is that you want to make sure you are using the best bamboo poles for your structure so it does not fall apart. But it is also to check which poles can be used for other parts of your structure. If there are splits running down the side of the bamboo pole, maybe it is ideal to be split in half and turned into a roofing tile. If the wall thickness is thicker than the average, maybe it is better suited as a structural column. Really investigating the quality of your bamboo poles will inform which piece can be used for which part of the structure.

There are a few essential factors to consider when quality checking your bamboo:

- Size. Each bamboo pole does not fit into an exact mould and will not match specific dimensions but it should fit into an average range within its species. If you find a bamboo pole that is significantly smaller, or even bigger, than the rest, it probably means that it is not suitable for structural purposes as it will not behave in the same way as the other poles of the same species. You should also look at the culm wall thickness to evaluate if your bamboo pole fits into an average thickness. For example, Dendrocalamus asper has an average wall thickness of 11-20mm.

- Condition. You should avoid using bamboo poles which already have cracks or splits running down the length of them. These cracks might have happened because of the treatment method, the drying process or even during the truck ride over to the site. Either way, it is best to set them aside as using them structurally might increase the size of the cracks. If the crack is only on a small portion of the pole but the majority of the pole seems intact and fit for structural use, then you can trim off the cracked portion.

- Moisture Content and Density. An average bamboo pole fit for construction after being treated should have a moisture content level of around 18%. Anything above or below that number will affect the structural integrity of the pole. To analyse this, you should firstly weigh the bamboo pole with your hands. If you feel that one pole is much heavier than the others, it might need more time to dry before being used for construction. If you want to be more precise, there are moisture measurement tools which can tell you the exact moisture content of your materials.

Running through these different characteristics will already inform you which poles are the best in the group for your structure. However, there are a couple of lessons to remember. First, do not throw away all the poles you do not end up using, some might become useful for other parts of your design. Second, remember that relativity is also crucial to take into account. Because bamboo poles are all so different from one another, you need to feel for the relative average of your selection to determine the group’s general quality.

3. Selecting the right bamboo for construction.

The bamboo you have received on-site has now been checked, sorted and categorised. All there is left to do is choose the right pole for the right part of your structure. It is easier said than done because the choice of pole depends on the physical attributes that the pole offers and those that you want for your design. Maybe you want a pole with a bend in a very specific place or you need a portion of bamboo that is almost completely straight. Either way, the choice of the bamboo pole is yours to make in the end and will define the success of your design, both structurally and aesthetically.

- The strongest parts of your pole’s anatomy are the nodes. They are recognisable as the swelling which happens on the bamboo’s skin rhythmically throughout the length of the pole. In the inside of the pole, the node is a small disk-like diaphragm which adds rigidity to the hollow bamboo pole. When you are designing with bamboo, your joinery should align with the pole’s nodes so that your joint sits closely to a node. This will make sure that your joint is stiff and strong. So when you are choosing your bamboo pole for a specific area in your structure, you should measure the distance between critical points and find a pole whose nodal rhythm mirrors that measurement.

- Similarly, certain parts of the bamboo pole are best suited for specific structural components. For species like Dendrocalamus asper, the lower part of the pole has nodes which are very close to one another, thicker culm wall thicknesses and wider culm diameters. For these reasons, we think that the lower part of the Dendrocalamus asper poles are well suited for lower, structural columns where most of the building’s weight will be applied. The middle part of a Dendrocalamus asper culm tends to be straighter with more regular nodes, which fits the criteria for beams.

- Lastly, you should choose your bamboo pole according to your aesthetic preferences. We do choose some of our poles simply because we think they would look great where we place them. The bottom of Dendrocalamus asper poles are very structural but they do also look really nice as “elephant” footings with river stones in our bamboo structures. Sometimes, we will choose a bamboo pole because it has the right curve or bend to mark the entrance of a space. Designing with a natural material should also be a fun and personal practice, and not only based on structural and mechanical properties.

When you are designing with bamboo, you need to consider that you are working with a natural material which has its own set of rules and boundaries. You can pick and choose amongst a selection of bamboo that will be handed to you on your construction site but at the end of the day, it is your responsibility to use that bamboo in the best possible way. You need to take into account what the bamboo wants to do but also how your design allows the material to shine.

We believe that selecting the right bamboo for your project actually starts with the seed and ends with a beautiful column for your project. Our Bamboo Online Immersion is programmed to teach you all you need to know about bamboo as a plant to then understand it better as a design and construction material.

After finishing her Masters of Architecture at the University of Hong Kong where she wrote her thesis about bamboo construction for the rural communities of Bali. Cécile was part of the Bamboo U Team as a Management Consulting Professional until 2023.

JUNE 13-24, 2025

The 11 Day Bamboo Build & Design Course in Bali

In 11 days, we'll show you how to build bamboo structures we’ll share all that it takes to build with nature.

Start Anytime

The Bamboo Harvesting Course

The Bamboo Harvesting Course is an online step-by-step training to harvest and care for your bamboo clumps to ensure their longevity and productivity. This maximizes the potential of this beautiful grass as a rapidly renewable resource.Whether you are an architect, builder, or sustainability enthusiast, this mini course will enable you to utilize this rapidly regenerative resource as a durable construction material.It will help remove any fear or doubt about the durability of bamboo and help you build reputable bamboo structures that stand the test of time!