Building A Disaster Relief Structure Out Of Bamboo

By Alumni | August 27, 2021 | Design - Resources - Construction -

During our Bamboo Immersion in December 2018, we set out to build a beautiful disaster relief multi-purpose structure, initiated by the Indonesian government with Arief Rabik, CEO of Environmental Bamboo Foundation (EBF). The prototype was in response to the earthquake which hit the Indonesian island of Lombok in August 2018 and the flash floods that ravaged the Sigi District, Central Sulawesi in October 2018.

In this article, we share some guidelines we adhered to when building a prototype disaster relief bamboo structure:

- Modular open-ended design

- Construction techniques

- Construction process and outputs

1. Modular open-ended design

The design for this prototype structure aimed to develop an efficient emergency shelter model that provides flexible space planning which can also evolve into multi-purpose usage according to the user’s needs by using a minimal amount of material.

Together with a lightweight engineer- Neil Thomas and Bamboo U students, we explored the bamboo split trussed arched system and with Arief Rabik, we decided to use this structural concept due to its material to stiffness ratio; using bamboo’s strongest property, tension, together with a basic truss triangulation system.

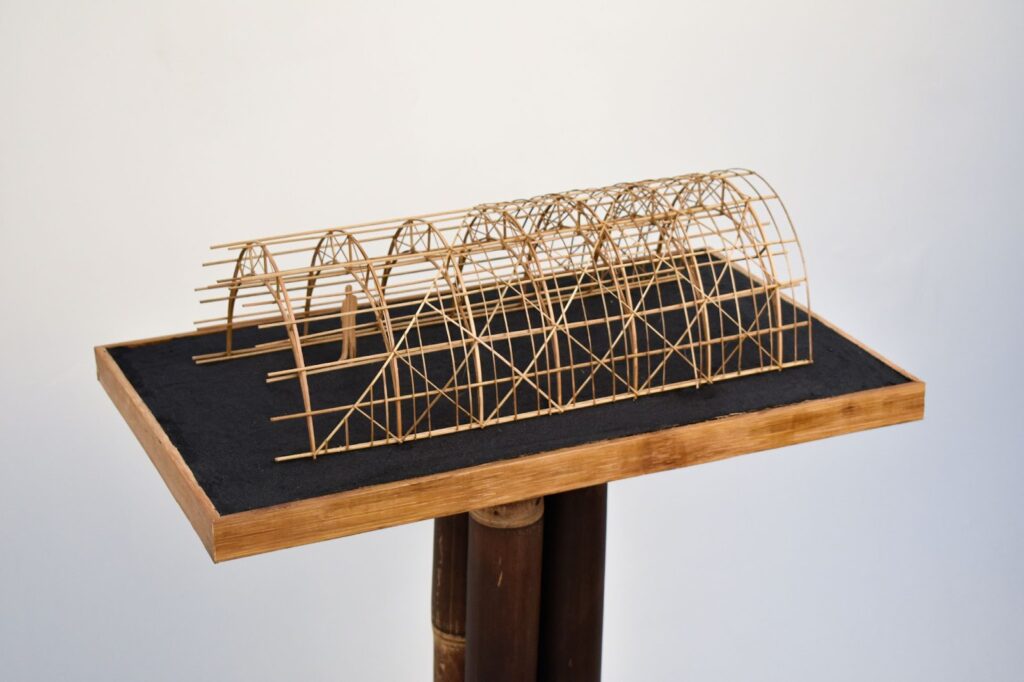

We created a few scaled models with different design and structural iterations which helped us better to understand the scale and proportions to produce a better design.

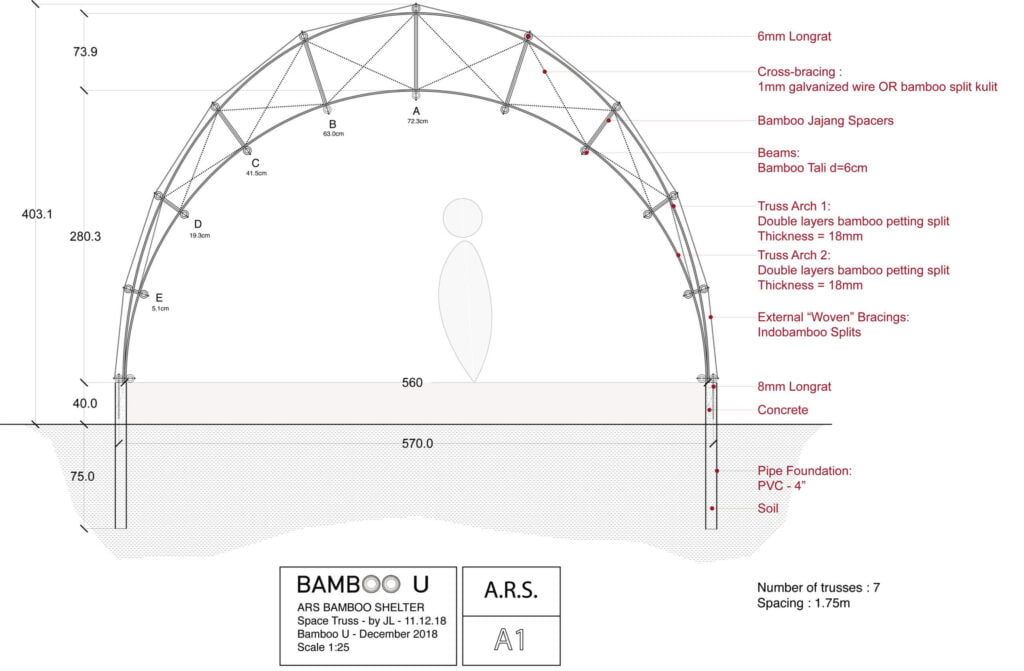

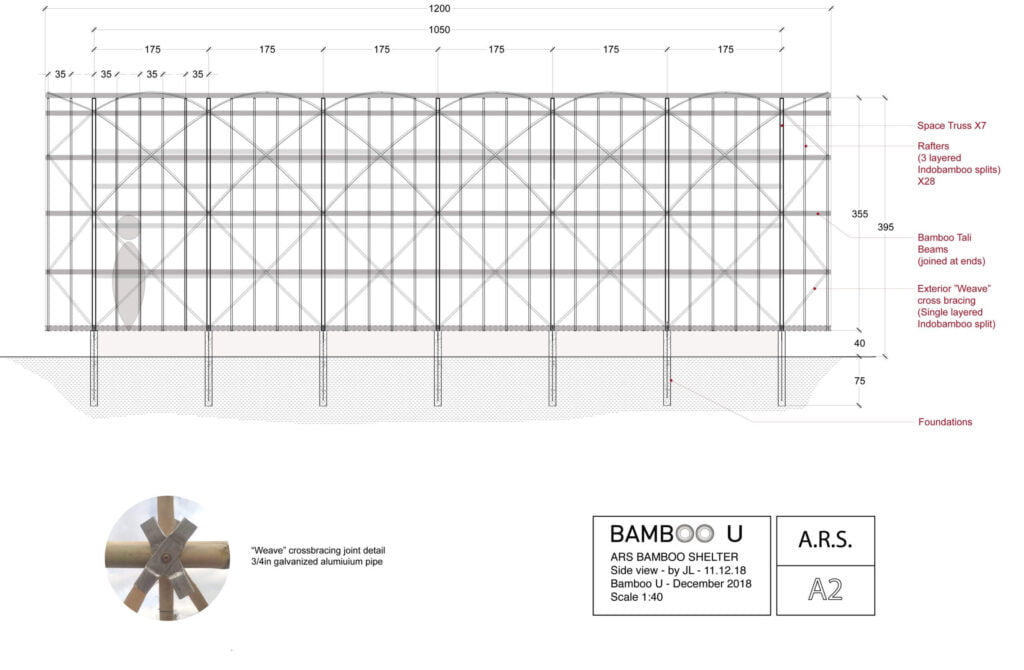

The final design was made up of a linear space structure with flexibility for space planning and a semi-circular, double-arched truss system that is strong and lightweight. These two components of 1) linear planning and 2) a semi-circular arched frame with a continuous curve gives the possibility of scaling the building up into larger and wider spans easily in the future if needed.

This prototype building is composed of seven arched members 5.7m wide, 3.6m high arches, placed at 1.75m intervals, of seventeen 12-m long Gigantochloa apus poles, with tie-beams connecting all the arches and a grid-shell using Dendrocalamus asper splits connected by metal brackets bracing in a spiral, overlapping above the structure to make it more stable.

2. Construction techniques

When building disaster relief structures it is important to build rapidly with simple construction techniques, with the possibility of scaling the structure up with minimum logistics required.

The three main elements to consider include:

Foundations

We’re not proud of it, but as things stand, reinforced cement concrete (R.C.C) is the only reliable, affordable, and fast option to create a strong base for a bamboo building. We can also produce precast R.C.C pile foundations easily if it is required in larger quantities.

Superstructure

Arched frames act as a superstructure and a major part of the whole construction process. The frames were designed to easily build with minimal material. We used split bamboo, which can be made easily by local farmers or carpenters. Bolt and metal brackets were used as joineries/connectors, this joinery technique can be built with minimal skill or experience in bamboo carpentry.

There are two ways to build the superstructure: 1) building the frames in place, which requires a certain amount of logistics, skill, and scaffolding and 2) building them using a template system, where the frames are drawn and built on the ground. The template system doesn’t require much logistics, skill, and a lot of scaffolding setup. Later the frames are put in place. Building using a template system helps to build faster and precise to the proportions. Template systems allow for the production of multiple frames very quickly.

Roofing

There are two ways to build the superstructure: 1) building the frames in place, which requires a certain amount of logistics, skill, and scaffolding and 2) building them using a template system, where the frames are drawn and built on the ground. The template system doesn’t require much logistics, skill, and a lot of scaffolding setup. Later the frames are put in place. Building using a template system helps to build faster and precise to the proportions. Template systems allow for the production of multiple frames very quickly.

3. Construction process and outputs

First, we cleared the site and stacked the points for the foundations on the ground. We used reinforced cement concrete (R.C.C) pile foundations 10 cm wide and 75cm deep for this building. We had 14 foundations 7 on either side of the building that acted as bases to hold the arch frames in place.

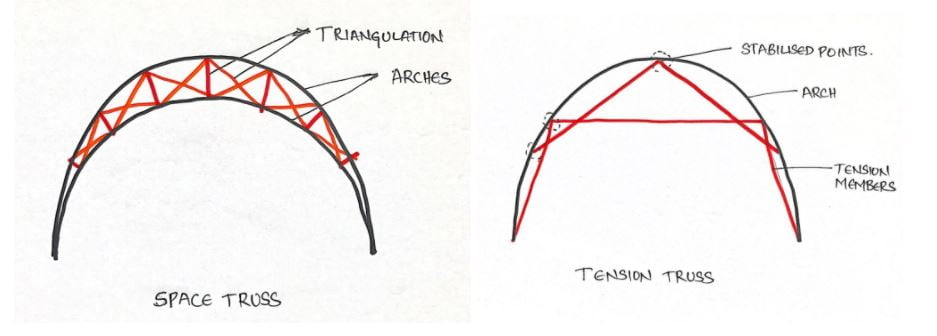

We built the arch frames on the ground using a template system. During the construction of the frames, we revised the design of the last 3 frames using a different tension truss system for experimental purposes. In the end, the structure features two different types of trusses: the first working as a space truss (a higher arch and a lower one kept 70cm apart using bamboo spacers and split triangulation), the second working as a tension truss (a single arch whose shape is stabilised by tension elements connecting distant points of its curve). This was a last minute on-site decision that worked perfectly and created one more structural concept that fit nicely into the design.

(On the left is a space truss and on the right is a tension truss)

The structure was assembled within 5 days by the Bamboo U students who for the most part had no previous experience in bamboo construction.

It is important to build prototypes and experiment with different aspects of the building process, especially considering the challenges of building disaster relief structures. This prototype was designed taking into consideration our local context, the materials available locally, rapid construction techniques, and minimum construction skills & logistics. Building this prototype has opened up a wide range of possibilities for further prototyping iterations to make more affordable and cost-effective structures. This structure is now used as a bamboo material storage for the Bamboo U workshops.

Article written by Sai Goutham & Maria Farrugia

A range of students and alumni from our online and in-person courses have contributed to our blog posts, and their details can be found in each article. They share their learnings, bamboo projects and experience with Bamboo U

June 7-18, 2024

The 11 Day Bamboo Build & Design Course in Bali

In 11 days, we'll show you how to build bamboo structures we’ll share all that it takes to build with nature.

April 26, 2024

The Fundamentals of Building with Bamboo Online Course

All the fundamentals you need to get you started working with bamboo. Deep dive into cinematic videos and step-by-step guides that will provide you with a strong understanding of bamboo as a design and building material.