Building Beautiful Bamboo and Stone Homes in Peru

By Octavio Van Praag | March 17, 2023 | Alumni Projects and Research -

A journey of building a house with bamboo roofing in the rainforests of the Chachapoya region of Peru.

A few years back I started designing and building with a strong ecological emphasis. At first with the elements at hand: clay, wood, stone. Of course, in my research, bamboo popped up very quickly as the most regenerative and sustainable construction material. And very quickly Ibuku showed up as one of the leading architecture firms in new ways of using bamboo in construction. From there, I came to know Bamboo U, and immediately wanted to learn more.

On the way, I came to do other bamboo courses and started building and designing simple structures with bamboo. Until an opportunity to build a house came up. Almost at the same time, the Bamboo U online course was being announced. So I knew I had a great opportunity to advance a design for the house, and have great support from the online course, with specific questions and doubts, especially on roofing systems.

Starting The Project

As I mentioned before, working with sustainable materials for construction inevitably directs you to bamboo. So in my architecture journey, I wanted to implement it more. After building an 8x8 paraboloid bamboo roof and a 6 m high hyperbolic tower, I felt ready to go further.

I had a beautiful land in front of one of the highest waterfalls in the world: the Gocta waterfall. But had no money to invest. Luckily, a friend of mine heard about my land and my dream and decided to invest, giving me full creative freedom. The Chachapoya region has very rocky soil, and its previous inhabitants did amazing stone construction. At the same time, the north of Peru is where most of the bamboo agroforestry projects are, including salt treatment systems. So I decided to reinterpret Chachapoya's round architecture, but with bamboo roofing.

Once I had a preliminary design, the Bamboo U online course started, and I was ready to take full advantage of it. Apart from the great online tutorials, there were opportunities for one-to-one questions, to solve our own design processes. I had the chance to develop technical details of my structure, and at the same time, I entered a network that supported future doubts in my process after the course had ended.

Developing The Design

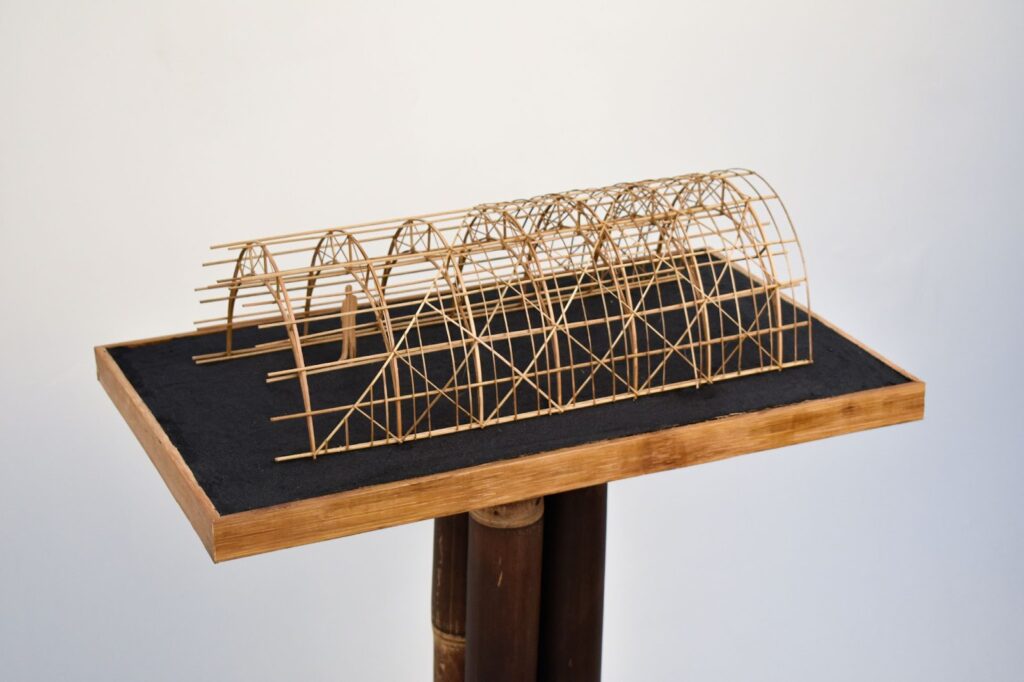

Although I had rough sketches and plans, the main contribution from the Bamboo U Online Course for me was making bamboo models. I could feel the structure itself in a material way, experiencing the weak parts. I could feel which bamboo split curve was too tight. And in this way, I adapted the design to its final form.

Simultaneously, I did 2D and 3D drawings and went back and forth from drawings to bamboo models. Once I had a final result, I worked with an engineer to calculate everything and go into details for joinery. Once again, we went back and forth, changing bits here and there, until I felt ready to go to the site. As this was going on, the amazing stone walls were being built, and the support for the roof was almost done!

Construction and Completion of Project

The region where the construction is lacks good hand work, carpenters, professionals. Luckily, I counted on a very good local friend who has experience in natural materials, although not so much with bamboo, and he managed the construction. He assembled a small but enthusiastic team that started with all the stone work. Amazingly, we used only stones from the same land, and it felt like sculpting the landscape.

As for the bamboo, there is a farmer 4 hours away which has an amazing Guadua forest, and already treats bamboo with borax and boric acid. We ordered the bamboo 5 months in advance, both poles, splits, and pelupuh (flattened bamboo roof shingles). When the bamboo arrived, the first obstacle came with it. I could immediately see many poles were not mature enough: they cracked inward. But time was ticking and I thought at that moment that there were not so many wrong poles.

I came to the site for 2 months to do the bamboo work hands-on, and guide the team in this new stage of the construction. So we started with a 17m long split beam, with 15 splits in one direction and 4 in the other. We had to plane split by split and put them together with wire along our template in the floor. After 3 days, the beam was ready, and we had to raise it up to its position and anchor it to the stone walls. Very exciting, however, we did not put enough stabilizers, and the beam moved like a jelly, twisting in all directions. But once we got it to place, it felt solid, with a 6 m span completely stable. We could even jump on it, and it didn't move an inch. After this, came the rafters for the roof, which were anchored to a centered ring planned originally with splits (the radius was too small for the splits we had, and had to adapt to a metal ring). Cutting the endpoint of the rafters to match the curve of the ring was time-consuming, as well as the inclined columns that had double angles, one at the bottom and another at the top. So we had to, very progressively, cut and sand the shape of these connection points very patiently. All very fun anyways! Once we got all the rafters into place, we covered the roof with splits, then covered the split surface with an asphalt membrane, and then, very new to all of us, put the pelupuh final layer of the roof, with a rough Guagua flatten bamboo that we had to cut with angles to get the right curve.

In all this process, many more poles started to crack inward, some of them already installed. So I realized that one of the biggest challenges, at least here in Peru, is to find a trustworthy supplier. At the same time, it is essential to train more in order to identify the right poles once harvested and dried. As for the handwork, I was lucky to have a very proactive and capable team, willing to learn fast. Many mistakes were made, and we all learned in the process. But it was worth it, as we saw the final result.

I think being committed to a dream, and also thinking ahead as our specie adapts to new challenges and contexts, gave me the strength to pursue this project, and to consider bamboo as its the protagonist.

What’s Next On Your Bamboo Journey?

As I am finishing the details in this house, its images have already captured interest. And 3 other projects are in the process of design. So I am grateful to have taken a risk, using techniques never used before here in Peru, and opening a world of possible projects.

In the journey of exploring techniques and materials, it is very likely to make many many mistakes. And I feel these mistakes are our best teachers, to later improve and evolve.

I was lucky to have an amazing network of lessons and people put together by the Bamboo U team, a web that is growing fast, and of which I am truly grateful to be part of.

If you would like to follow my work and future projects: www.instagram.com/praag_arquitectura/

Architect specialized in sustainable construction.

OCTOBER 10-21, 2025

The 11 Day Bamboo Build & Design Course in Bali

In 11 days, we'll show you how to build bamboo structures we’ll share all that it takes to build with nature.

Start Anytime

The Bamboo Harvesting Course

The Bamboo Harvesting Course is an online step-by-step training to harvest and care for your bamboo clumps to ensure their longevity and productivity. This maximizes the potential of this beautiful grass as a rapidly renewable resource.Whether you are an architect, builder, or sustainability enthusiast, this mini course will enable you to utilize this rapidly regenerative resource as a durable construction material.It will help remove any fear or doubt about the durability of bamboo and help you build reputable bamboo structures that stand the test of time!